Case Studies

Real-world results from engineered compressed air projects — improving efficiency, reducing downtime, and supporting critical operations across the UK.

Proven Solutions, Documented Outcomes

Explore selected case studies showing how Compressed Air Systems UK supports businesses with compliant, energy-focused compressed air systems — from upgrades and optimisation through to specialist applications.

If you’d like to discuss a similar project, our team can advise on specification, installation, servicing, and whole-life performance.

Armac Martin’s Sustainable Manufacturing Transformation

How a sustainable compressed air upgrade supported performance improvements and reduced environmental impact.

Saving Energy in Tight Spaces

Upgrading an ageing compressor to a demand-matched system to improve productivity and reduce waste.

Boosted by Coltri

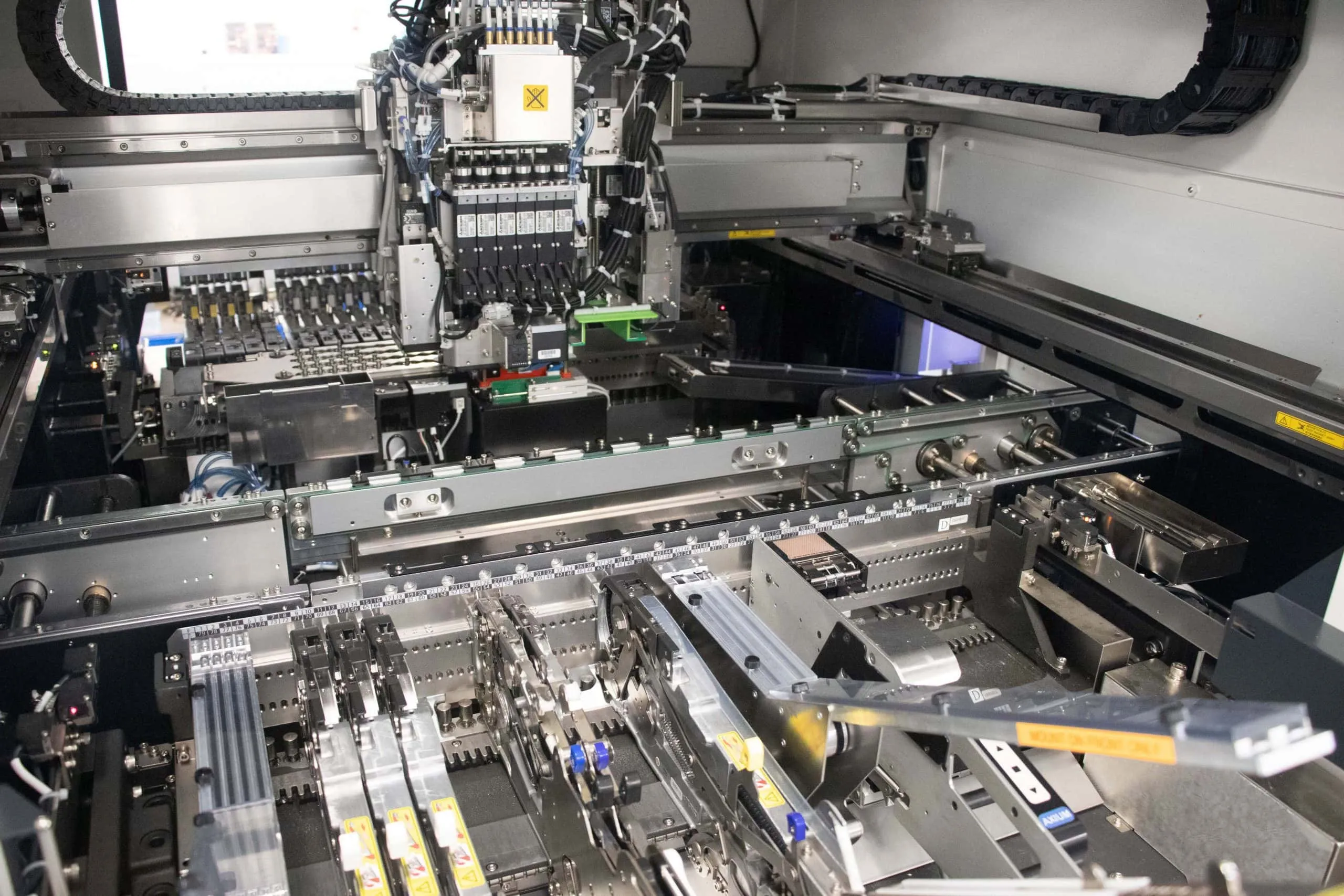

Modernising a booster setup supporting production-critical equipment, improving reliability and output.

Crashing Down Costs

Replacing older compressors with energy-efficient technology to reduce running costs and support sustainability.

Exhibiting Financial Savings Through Reduced Energy Consumption

A long-serving compressor replaced with modern equipment to improve efficiency and reduce operating expenditure.

Industries We Support

Support & Aftercare

Our Expert Services

24/7 EMERGENCY BREAKDOWN

Rapid response for all air compressor malfunctions, anytime you need us.

View ServiceINSTALLATIONS

Expert design and bespoke pipework installations tailored to your site.

View ServiceSERVICING

Comprehensive maintenance to keep your air systems running at peak performance.

View ServiceVISIT OUR TRADE COUNTER

Come meet our experts in person at our dedicated Birmingham trade hub.

Get DirectionsSHOP NOW

Browse our full range of air compressors, parts, and industrial tools online.

Go To ShopCONTACT US

Have a question? Reach out to our team today for expert advice and support.

Send Message