Did you know that connecting multiple air compressors can boost your system’s efficiency by up to 30% while ensuring uninterrupted airflow for demanding operations?

At Compressed Air Systems UK, with over 30 years of expertise in the air compressor industry, we’ve seen businesses transform their operations by optimising their compressed air systems. Whether you’re running a small workshop or a large industrial facility, understanding how to connect multiple air compressors can be a game-changer. But is it the right solution for you? Let’s dive into the pros, cons, and a step-by-step guide to help you make an informed decision.

Key Areas We Will Cover

- Benefits of connecting multiple air compressors

- Potential drawbacks to consider

- Step-by-step guide to setting up a multi-compressor system

- The importance of having a backup compressor

- Best practices for maintenance and efficiency

- Frequently asked questions about multi-compressor systems

- How Compressed Air Systems UK can support your setup

Introduction

Connecting multiple air compressors is a strategy many businesses adopt to meet high air demand, improve system reliability, and enhance energy efficiency. At Compressed Air Systems UK, we specialise in tailoring compressed air solutions to your needs, whether you’re using petrol, diesel, base mount, or electric air compressors. This guide explores the advantages and challenges of linking multiple air compressors, provides a practical how-to for seamless integration, and highlights the value of a backup compressor. With our 30 years of industry experience, we’re here to ensure your system runs smoothly and efficiently.

-

Sale!Add to basket

Sale!Add to basket£3,934.00Original price was: £3,934.00.£3,737.30Current price is: £3,737.30. exc vat. -

Sale!Add to basket

Sale!Add to basket£5,944.00Original price was: £5,944.00.£5,646.80Current price is: £5,646.80. exc vat. -

Sale!Add to basket

Sale!Add to basket£11,400.00Original price was: £11,400.00.£6,840.00Current price is: £6,840.00. exc vat. -

Sale!Add to basket

Sale!Add to basket£7,522.00Original price was: £7,522.00.£7,145.00Current price is: £7,145.00. exc vat. -

Sale!Add to basket

Sale!Add to basket£8,565.00Original price was: £8,565.00.£7,817.26Current price is: £7,817.26. exc vat. -

Sale!Add to basket

Sale!Add to basket£4,532.00Original price was: £4,532.00.£4,305.40Current price is: £4,305.40. exc vat.

Why Connect Multiple Air Compressors?

Increased Air Capacity

Running a single compressor for high-demand applications can strain the system, leading to wear and inefficiency. By connecting multiple air compressors, you can:

- Meet higher air volume requirements for large-scale operations.

- Support multiple tools or machines simultaneously.

- Avoid downtime due to insufficient air supply.

Enhanced Reliability

A multi-compressor setup offers redundancy, ensuring your operations continue even if one unit fails. This is critical for industries where downtime can result in significant losses.

Energy Efficiency

Using smaller air compressors in tandem can be more energy-efficient than running a single large unit continuously. You can activate only the units needed for the task, reducing energy waste.

Scalability

As your business grows, a multi-compressor system allows you to add units without replacing existing equipment, offering a cost-effective way to scale.

Potential Drawbacks of Connecting Multiple Air Compressors

Higher Initial Costs

Setting up multiple air compressors requires investment in additional units, pipework, and installation services. While the long-term benefits often outweigh the costs, the upfront expense can be a hurdle.

Complex Installation

Connecting multiple air compressors demands precise planning to ensure proper integration. Incorrect setups can lead to inefficiencies or system failures.

Increased Maintenance

More air compressors mean more components to service. Regular maintenance, such as air receiver inspections and leak detection, becomes critical to avoid costly repairs.

Space Requirements

Multiple air compressors require adequate space, which may be a challenge for smaller facilities.

How to Connect Multiple Air Compressors: A Step-by-Step Guide

Step 1: Assess Your Air Demand

Before connecting air compressors, calculate your total air demand. Consider:

- The number of tools or machines in use.

- Peak air consumption periods.

- Future expansion plans.

Our experts at Compressed Air Systems UK can conduct an energy-saving audit to determine your exact requirements.

Step 2: Choose Compatible Air Compressors

Ensure all air compressors are compatible in terms of pressure ratings and control systems. Mixing petrol, diesel, or electric air compressors may require additional configuration.

Step 3: Design the Pipework System

Proper pipework is essential for efficient airflow. Work with professionals to:

- Install appropriately sized pipes to minimise pressure drops.

- Use high-quality materials to prevent leaks.

- Incorporate shut-off valves for each compressor to allow independent operation.

Compressed Air Systems UK offers professional pipework and installation services to ensure a robust setup.

Step 4: Configure the Control System

A central control system can synchronise the operation of multiple air compressors, optimising load distribution and energy use. Modern controllers can alternate compressor usage to balance wear.

Step 5: Test for Leaks and Efficiency

After installation, conduct leak detection and air quality testing to ensure the system operates at peak performance. Regular testing helps maintain compliance with industry standards.

Step 6: Schedule Regular Maintenance

To keep your multi-compressor system running smoothly, schedule:

- Routine air receiver inspections.

- Compressed air service and maintenance.

- Energy-saving audits to identify inefficiencies.

Our 24/7 emergency breakdown assistance ensures you’re never left stranded.

The Importance of Having a Backup Compressor

A backup compressor is a critical component of a multi-compressor system, providing an extra layer of reliability and peace of mind. Here’s how it benefits your business:

Minimised Downtime

If a primary compressor fails or requires maintenance, a backup compressor ensures your operations continue without interruption. This is especially vital for businesses where downtime can lead to lost revenue or missed deadlines.

Cost Savings

By preventing production halts, a backup compressor saves you from the financial impact of downtime. For example, industries like automotive repair or manufacturing can lose thousands of pounds per hour if operations stop.

Extended System Lifespan

Using a backup compressor allows you to rotate usage among units, reducing wear on individual air compressors and extending their overall lifespan. This balanced approach also lowers long-term maintenance costs.

Flexibility During Maintenance

Scheduled maintenance, such as air receiver inspections or filter changes, can be performed without disrupting operations. A backup compressor keeps your system running while primary units are serviced.

Support for Peak Demand

During periods of high air demand, a backup compressor can supplement your primary units, ensuring consistent performance without overloading your system.

Compressed Air Systems UK can help you select and integrate a backup compressor that seamlessly fits your multi-compressor setup, ensuring maximum reliability.

Best Practices for Maintaining a Multi-Compressor System

- Monitor Performance Regularly: Use sensors to track pressure, temperature, and energy consumption.

- Conduct Leak Detection: Even small leaks can lead to significant energy losses over time.

- Rotate Compressor Usage: Alternate which air compressors run, including the backup, to distribute wear evenly.

- Invest in Quality Testing: Regular air quality testing ensures compliance with industry standards.

- Partner with Experts: Work with experienced providers like Compressed Air Systems UK for maintenance and emergency support.

Why Choose Compressed Air Systems UK?

With over 30 years in the air compressor industry, Compressed Air Systems UK offers unparalleled expertise and a wide range of services tailored to your needs. From new installations to emergency call-outs, our team is dedicated to keeping your systems running efficiently. Our customers, like Richard Vinten and Amelia Blackwell, praise our quick response times and professional service, making us a trusted partner for businesses across the UK.

Conclusion

Connecting multiple air compressors can significantly enhance your operation’s efficiency, reliability, and scalability, but it requires careful planning and maintenance. By incorporating a backup compressor, you can minimise downtime, extend system lifespan, and handle peak demand with ease. Our step-by-step guide and answers to common questions provide the tools you need to create a robust system. At Compressed Air Systems UK, we’re here to guide you every step of the way with our expert services and industry-leading solutions.

Ready to Optimise Your Compressed Air System?

Contact Compressed Air Systems UK today for a free consultation or energy-saving audit. Let our 30 years of experience help you build a reliable, efficient multi-compressor system tailored to your needs. Visit our services page or use our quick quote tool to get started!

Frequently Asked Questions About Connecting Multiple Air Compressors

Have questions about setting up a multi-compressor system? We’ve compiled answers to the most common queries to help you make informed decisions about your compressed air setup.

Yes, but it requires careful planning. Ensure all air compressors have compatible pressure ratings and control systems. Professional installation from Compressed Air Systems UK can help integrate mixed systems effectively.

If your operations experience frequent downtime due to insufficient air supply or if you anticipate future growth, a multi-compressor system may be beneficial. Our energy-saving audits can assess your needs.

Costs vary based on the number of air compressors, pipework, and control systems required. Contact Compressed Air Systems UK for a tailored quote using our quick quote tool.

Regular maintenance, including air receiver inspections and leak detection, should be conducted at least annually or as recommended by your provider. Compressed Air Systems UK offers comprehensive service plans to keep your system in top condition.

Yes, by using only the air compressors needed for a specific task, you can reduce energy consumption compared to running a single large compressor continuously.

Explore More of Our Articles

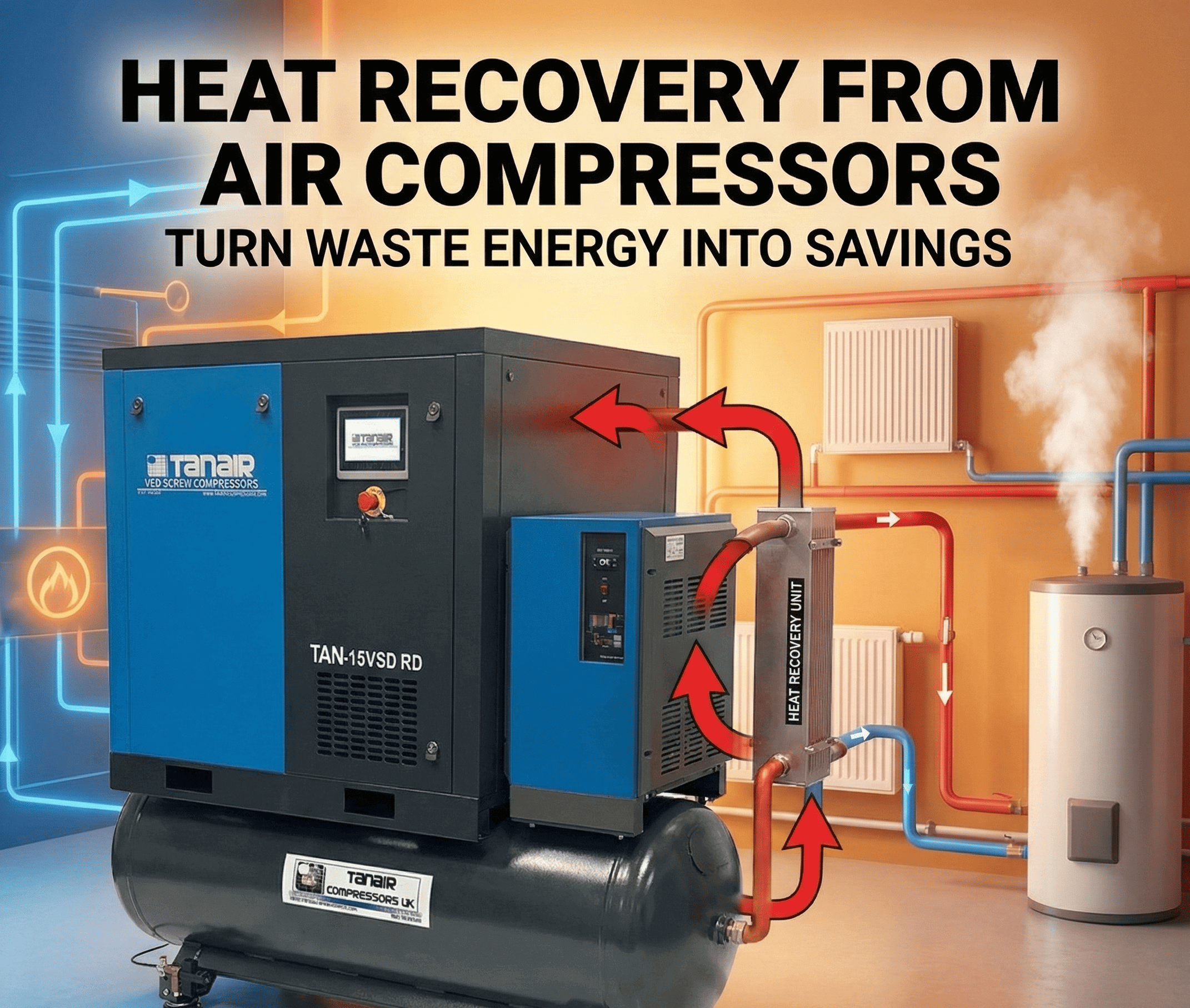

Heat Recovery from Air Compressors: Turn Waste Energy into Savings for UK Workshops 2026

What if up to 94% of the energy used by your air compressor is converted into heat, much of which is simply wasted, potentially costing

The Ultimate Guide to Air Line Fittings: Types, Uses, and Maintenance for UK Workshops

Did you know that poor quality air line fittings can cause up to 30% energy loss in compressed air systems, costing UK workshops thousands in

The Benefits of Deep Cleaning Your Compressed Air System

Did you know that accumulated contaminants in compressed air systems can cause up to 30% energy waste, adding thousands to annual electricity costs for UK

Wall-Mounted Air Compressors: The Ultimate Space-Saving Guide for UK Garages in 2025/26

Did you know that the average UK garage loses up to 2 square metres of valuable floor space to a traditional air compressor – enough

Air Compressor Kits vs Standalone Tools: Which Setup Saves You Time and Money in the UK?

Did you know that over 70% of UK DIY enthusiasts end up spending an extra £150 or more piecing together mismatched air tools that fail

The True Cost of Compressor Downtime in Tamworth’s Industrial Sector

Did you know that a single hour of compressor downtime in a mid-sized manufacturing plant can cost up to £10,000 in lost production alone? In