Did you know that accumulated contaminants in compressed air systems can cause up to 30% energy waste, adding thousands to annual electricity costs for UK businesses?

“Deep cleaning is not merely routine upkeep; it restores peak efficiency, prevents costly failures, and ensures clean air delivery,” emphasise experts at leading compressed air specialists.

What You’ll Learn

- Hidden risks from contaminants like moisture, oil, and debris in compressed air systems

- Proven benefits, including substantial energy savings and reduced downtime

- Practical methods for deep cleaning tanks, lines, dryers, and components

- When professional services, including chemical pressure cleaning, deliver the best results

- Ongoing maintenance strategies suited to UK conditions

- Real cost savings and compliance advantages for workshops and industries

Introduction

Deep cleaning compressed air systems goes beyond daily draining or filter swaps. It involves thorough removal of built-up moisture, oil residues, rust, scale, and particulates from tanks, pipework, dryers, and filters. In the UK, with escalating energy prices and rigorous environmental rules, regular deep cleaning optimises performance, cuts costs, and extends equipment life. This guide details the benefits and methods, helping UK users from garages to factories maintain reliable systems.

The Hidden Dangers of Contaminant Buildup

Compressed air systems draw in ambient air, which carries moisture, dust, and pollutants. Over time, these condense and accumulate:

- Rust and corrosion inside tanks

- Blocked filters and restricted airflow

- Oil aerosols contaminating downstream tools

- Bacterial growth in wet environments

Unchecked buildup leads to pressure drops, higher energy use, and premature component failure.

Key Benefits of Deep Cleaning Compressed Air Systems

Professional deep cleaning yields tangible returns for UK operations.

Significant Energy Savings

Clean systems minimise resistance. Removing deposits restores efficiency, potentially reducing consumption by 10–30% and saving hundreds annually on bills.

Prolonged Equipment Lifespan

Contaminants accelerate wear on seals, valves, and motors. Deep cleaning prevents corrosion and extends service intervals.

Superior Air Quality and Reliability

Pure, dry air avoids tool damage, product spoilage in sensitive sectors, and health hazards.

Minimised Downtime and Repairs

Proactive cleaning cuts unplanned stoppages by up to 50%, lowering repair expenses.

Environmental and Regulatory Compliance

Efficient systems reduce emissions. Proper condensate handling meets UK discharge standards, preventing fines.

Professional Deep Cleaning in Action

Our team at Compressed Air Systems UK employs specialised techniques for thorough results. Using pressure chemical guns, engineers safely apply approved solutions to break down stubborn residues on heat exchangers, dryers, and internals without disassembly where possible.

This method excels at removing oil, scale, and grime efficiently, restoring cooling efficiency and airflow.

Step-by-Step Deep Cleaning Guide

For smaller systems, follow these steps; larger installations require experts.

- Isolate and Depressurise: Switch off power and release pressure.

- Drain Condensate: Empty the tank completely.

- Clean Filters and Intakes: Replace or wash elements; clear vents.

- Flush Lines and Tank: Use approved cleaners or pressure methods for internals.

- Service Dryers: Clean or regenerate desiccant/refrigerant units.

- Inspect and Test: Check seals; run system and monitor.

Schedule deep cleans annually or biannually.

When to Choose Professional Services

Industrial systems gain from specialist tools like ultrasonic detection, chemical flushing, and high-pressure application. Compressed Air Systems UK provides nationwide support with minimal disruption.

Best Practices for UK Environments

Damp climates heighten moisture issues. Combine deep cleans with quality dryers and leak audits.

Conclusion

Deep cleaning compressed air systems delivers energy efficiency, reliability, longevity, and compliance benefits essential for UK competitiveness. Addressing contaminants head-on safeguards operations and reduces costs long-term.

Secure Your System’s Performance: Book a Deep Clean Today

Prevent efficiency losses from buildup. Contact Compressed Air Systems UK for a professional audit and deep cleaning service. Visit us or call 0121 753 3330. Access 24/7 emergency support for peace of mind.

Explore More of Our Articles

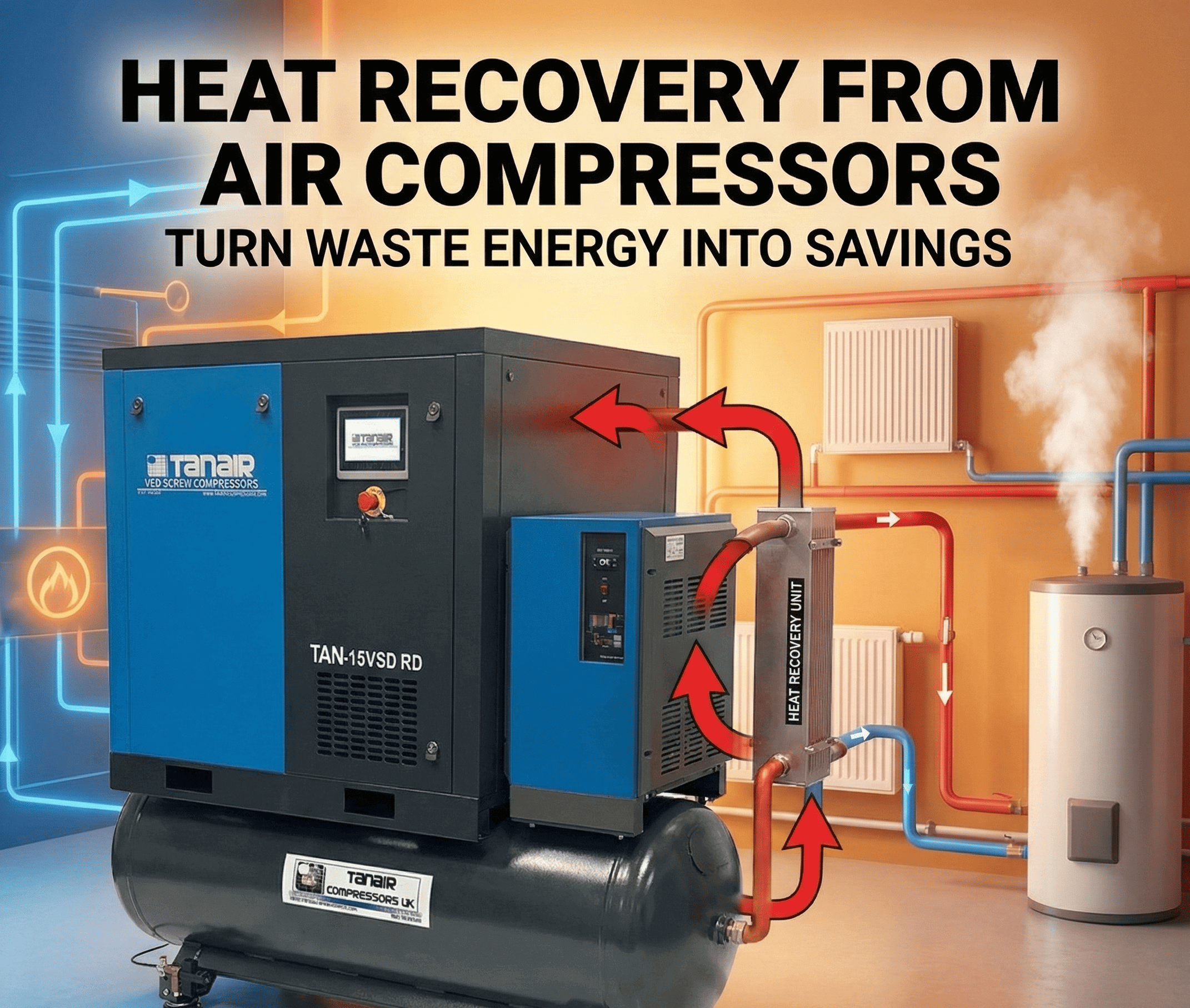

Heat Recovery from Air Compressors: Turn Waste Energy into Savings for UK Workshops 2026

What if up to 94% of the energy used by your air compressor is converted into heat, much of which is simply wasted, potentially costing

The Ultimate Guide to Air Line Fittings: Types, Uses, and Maintenance for UK Workshops

Did you know that poor quality air line fittings can cause up to 30% energy loss in compressed air systems, costing UK workshops thousands in

Wall-Mounted Air Compressors: The Ultimate Space-Saving Guide for UK Garages in 2025/26

Did you know that the average UK garage loses up to 2 square metres of valuable floor space to a traditional air compressor – enough

The True Cost of Compressor Downtime in Tamworth’s Industrial Sector

Did you know that a single hour of compressor downtime in a mid-sized manufacturing plant can cost up to £10,000 in lost production alone? In

Air Compressor Kits vs Standalone Tools: Which Setup Saves You Time and Money in the UK?

Did you know that over 70% of UK DIY enthusiasts end up spending an extra £150 or more piecing together mismatched air tools that fail

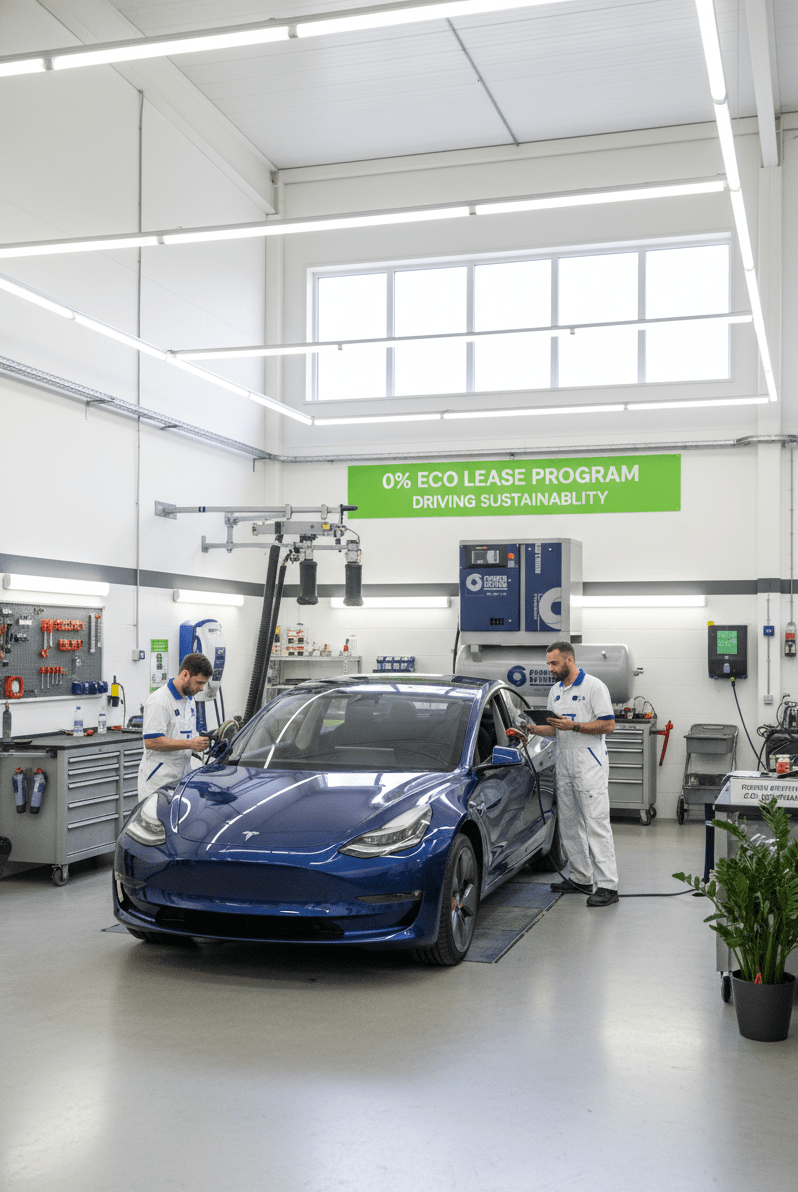

Energy-Efficient Car Body Repairs: Driving Sustainability with a 0% ECO Lease

Did you know that adopting energy-efficient practices in car body repairs can cut costs, boost your reputation, and reduce your environmental footprint? With the launch