Did you know that choosing the wrong air compressor can increase your energy costs by up to 30% and lead to costly downtime?

“Air compressors are the backbone of countless industries, yet selecting the right one can make or break your operational efficiency.” – Compressed Air Systems UK Expert

Key Areas We Will Cover

- Overview of air compressor types and their applications

- Key factors for choosing the right compressor in the UK

- Sizing and capacity considerations for optimal performance

- Energy efficiency and cost-saving technologies

- Maintenance tips to extend compressor lifespan

- Industry-specific requirements and regulations

- Top brands and models available in the UK

- Frequently asked questions about air compressors

Air compressors are essential for industries, workshops, and DIY enthusiasts across the UK, powering tools, manufacturing processes, and more. However, selecting the right compressor involves understanding types, specifications, and application needs. This comprehensive guide, crafted by Compressed Air Systems UK, explores everything you need to know to choose, use, and maintain air compressors for maximum efficiency and reliability.

Types of Air Compressors and Their Applications

Air compressors vary in design and function, each suited to specific tasks.

Piston (Reciprocating) Compressors

- How They Work: Use pistons to compress air, ideal for intermittent use.

- Applications: DIY projects, small workshops, tyre inflation, and nail guns.

- Pros: Affordable, portable, and suitable for high-pressure tasks.

- Cons: Noisy and less suited for continuous operation.

Rotary Screw Compressors

- How They Work: Twin screws compress air continuously, designed for heavy-duty use.

- Applications: Manufacturing, automotive, and industrial processes.

- Pros: Quiet, energy-efficient, and reliable for 24/7 operation.

- Cons: Higher upfront cost but better long-term value.

Centrifugal Compressors

- How They Work: Use rotating impellers for high-volume air delivery.

- Applications: Large-scale industries like petrochemicals and power plants.

- Pros: High output and efficiency for large systems.

- Cons: Expensive and complex, not suited for smaller operations.

Oil-Free vs. Oil-Lubricated Compressors

- Oil-Free: Ideal for food, pharmaceutical, and electronics industries requiring Class 0 air purity (ISO 8573-1).

- Oil-Lubricated: Durable for general industrial use but requires filtration to prevent contamination.

Tandem and Basemount Compressors

- Tandem: Dual-pump systems for high output, like Tanair’s TAN3BD-270/3T with 30cfm capacity.

- Basemount: Compact, stationary units for workshops with limited space.

Choosing the Right Air Compressor in the UK

Selecting a compressor involves matching specifications to your needs.

Key Factors to Consider

- Power Source: Electric (230V/110V), petrol, or diesel. Electric suits indoor use; petrol/diesel for remote sites.

- Tank Size: From 6L for DIY tasks to 270L for industrial needs. Multiply tool SCFM by 6 for minimum tank size.

- Pressure (Bar/PSI): Most tools require 6-8 bar (90-120 PSI). Check tool specifications.

- Flow Rate (CFM): Ensure compressor output matches tool requirements (e.g., 8 SCFM for an impact wrench).

- Portability: Portable for site work or stationary for workshops.

- Noise Levels: Silent models (e.g., Hyundai 8L at 60 dB) for noise-sensitive environments.

UK-Specific Considerations

- Regulations: Comply with BS EN 12021 for breathing air and ISO 8573-1 for purity.

- Climate: High UK humidity requires effective dryers to prevent moisture damage.

- Energy Costs: With rising prices, prioritise energy-efficient models like VSD compressors.

Sizing and Capacity Considerations

Correct sizing prevents underperformance or wasted energy.

How to Size Your Compressor

- List Tool Requirements: Check CFM (Cubic Feet per Minute) in tool manuals.

- Calculate Total Demand: Add 20% to account for simultaneous use or future expansion.

- Match Tank Size: Larger tanks (e.g., 50L-270L) suit continuous tasks; smaller (6L-24L) for intermittent use.

- Consider Duty Cycle: Piston compressors have 50% duty cycles; rotary screws run continuously.

For example, a 24L compressor suits DIY tasks like nailing, while a 100L+ unit is better for spray painting or industrial tools.

Now only

£4,083.00 Original price was: £4,083.00.£2,551.00Current price is: £2,551.00. exc vat.

TAN-S-5.5VSD (415V)

Energy-efficient 5.5kW (7.5HP) PM VSD screw air compressor delivering 19 CFM (0.55 m³/min) at 10 bar. Variable speed control helps reduce electricity consumption by up to 35% compared with fixed-speed compressors. Air-cooled, IP55 motor. 415V / 50Hz / 3-phase industrial supply. Ideal for UK workshops and light industrial use.Now only

£5,652.00 Original price was: £5,652.00.£3,750.00Current price is: £3,750.00. exc vat.

TAN-S-11VSD (415V)

Industrial 11kW (15HP) PM VSD screw air compressor delivering 46 CFM (1.3 m³/min) at 10 bar. Variable speed technology reduces wasted power and supports stable pressure, with potential energy savings up to 35% vs fixed-speed. Air-cooled, IP55 motor. 415V / 50Hz / 3-phase supply. Suitable for UK industrial use.Now only

£9,221.00 Original price was: £9,221.00.£5,717.00Current price is: £5,717.00. exc vat.

TAN-S-22VSD (415V)

High-output 22kW (30HP) PM VSD screw air compressor delivering 113 CFM (3.2 m³/min) at 10 bar. Variable speed control matches air demand to reduce electricity usage (up to 35% potential savings) and improve efficiency. Air-cooled, IP55 motor. 415V / 50Hz / 3-phase industrial supply. Ideal for high-demand UK industry.Now only

£4,269.00 Original price was: £4,269.00.£3,500.00Current price is: £3,500.00. exc vat.

TAN-S-7.5VSD (415V)

High-efficiency 7.5kW (10HP) PM VSD rotary screw air compressor delivering 32 CFM (0.9 m³/min) at 10 bar. Permanent magnet variable speed control can reduce energy use by up to 35% and maintain stable pressure under changing demand. Air-cooled, IP55 motor. 415V / 50Hz / 3-phase. Ideal for UK workshops and manufacturing.Now only

£883.00 Original price was: £883.00.£838.85Current price is: £838.85. exc vat.

Energy Efficiency and Cost-Saving Technologies

Energy-efficient compressors reduce costs and environmental impact.

Key Technologies

- Variable Speed Drives (VSDs): Adjust motor speed to demand, saving 10-20% on energy.

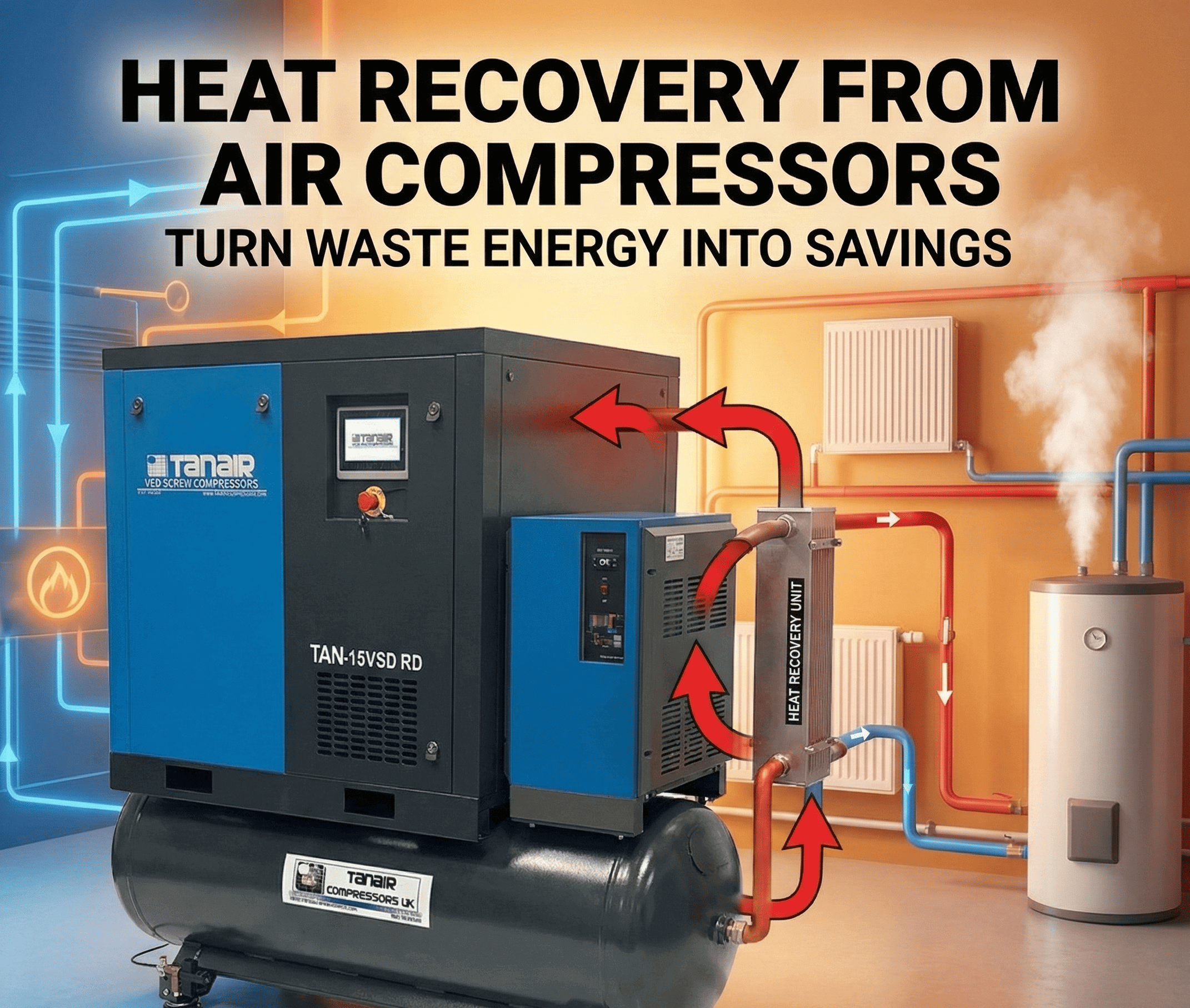

- Heat Recovery Systems: Reuse 70-94% of waste heat for heating or hot water.

- Energy-Efficient Motors: Permanent Magnet motors offer superior efficiency over traditional models.

- Smart Controllers: Optimise output and reduce idle time.

A UK manufacturing plant saved £15,000 annually by installing VSD compressors after an audit.

Tips for Efficiency

- Conduct regular air audits to identify leaks (up to 40% air loss).

- Use modular piping (e.g., AIRnet) to minimise pressure drops.

- Opt for low-maintenance oil-free compressors for sensitive applications.

Maintenance Tips for Longevity

Proper maintenance extends compressor life and ensures reliability.

Essential Maintenance Practices

- Daily: Check oil levels (for lubricated models) and drain receiver tanks to remove moisture.

- Weekly: Inspect hoses, fittings, and belts for wear.

- Quarterly: Replace filters and test air quality per ISO 8573-1 standards.

- Annually: Service by certified engineers, checking valves, motors, and lubricants.

Common Issues to Watch

- Leaks: Use ultrasonic detectors for early identification.

- Overheating: Ensure proper ventilation and clean coolers regularly.

- Pressure Drops: Inspect piping and fittings for blockages.

Regular maintenance can reduce downtime by 25% and extend equipment life by years.

Industry-Specific Requirements and Regulations

Different sectors have unique needs and standards.

Food and Beverage

- Requires Class 0 or 1 air to prevent contamination (ISO 8573-1).

- Follow BCAS Food Grade Compressed Air Code of Practice.

Pharmaceuticals and Healthcare

- Class 0 air for sterility; regular testing for bacteria and oil.

- Compliance with MHRA and BS EN 12021 for breathing air.

Automotive and Manufacturing

- Instrument air (Class 2-3) for tools and paint spraying.

- Focus on energy efficiency to reduce high operational costs.

Construction and Mobile Use

- Petrol/diesel compressors for site flexibility.

- Ensure robust fittings to withstand harsh conditions.

Top Air Compressor Brands and Models in the UK

The UK market offers diverse options from trusted brands.

Recommended Brands

- Tanair (Compressed Air Systems UK): Known for durable petrol, diesel, and electric models with features like dampener systems for reduced vibration.

- Power Systems: Affordable, low-noise oil-free compressors (e.g., HY7524, 24L, 5.2cfm).

- Fini: Reliable for DIY with long warranties

- NuAir: Part of the FINI-NUAIR group, offering high-quality piston and screw models.

Top Models for 2025

- Nuair NB4/200 FM4 (230 Volt)┃18 CFM 11 Bar Air Compressor on a 200 Litre Receiver

- Fini MINI CUBE 2.2-08-90 400 Volt | 10.3 CFM 8 Bar Plug & Play Air Compressor with 90 Litre Air Receiver

- Nuair NB3800B/3M/50 Q TECH PRO UK (230 Volt) (13 Amp) | 13.06 CFM Piston Air Compressor

In summary, selecting the right air compressor in the UK requires understanding your application, sizing needs, and efficiency goals. From piston models for DIY to rotary screw compressors for industry, the right choice enhances productivity and reduces costs. With proper maintenance and energy-saving technologies, you can ensure long-term performance and compliance with UK standards.

Ready to Find Your Perfect Air Compressor?

Contact Compressed Air Systems UK at 0121 753 3330 or visit Unit 15, Fortnum Close, Birmingham, B33 0LG, for expert advice and tailored solutions. Explore our range of Tanair compressors and get a free consultation today!

Frequently Asked Questions About Air Compressors

Got questions about choosing or maintaining an air compressor? Our FAQ section addresses common queries to guide your decision.

For DIY tasks like tyre inflation or nailing, a 6-24L compressor with 4-8cfm is sufficient. Larger tasks like spray painting require 50L+.

Oil-free models are ideal for clean air applications (e.g., food or electronics) but may have shorter lifespans. Oil-lubricated compressors are durable but need filtration.

Use VSDs, fix leaks, and conduct annual audits to optimise efficiency.

Direct-drive models are compact and low-maintenance, ideal for light use. Belt-drive compressors are quieter and suited for heavy, continuous tasks.

Service annually by certified engineers and perform daily/weekly checks for oil, moisture, and wear.

Explore More of Our Articles

The Ultimate Guide to Diesel Air Compressors: Power, Portability, and Performance for UK Applications

The Ultimate Guide to Diesel Air Compressors: Power, Portability, and Performance for UK Applications Everything UK professionals need to know about diesel air compressors —

The Ultimate Guide to Petrol Compressors: Portable Power for UK Sites and Workshops

The Ultimate Guide to Petrol Compressors: Portable Power for UK Sites and Workshops Everything UK tradespeople and site managers need to know about petrol compressors

Explore Our Complete Air Compressor Range

Shop the Full Tanair Air Compressor Range Compare portable direct drive, belt-driven workshop and energy-saving VSD compressors — then buy online, call for instant advice,

What Size Air Compressor Do You Need? (CFM, Tank Size & Power Guide UK)

What Size Air Compressor Do I Need? Use this UK-focused guide to calculate CFM, choose the right tank size, and match voltage & duty cycle—then

Heat Recovery from Air Compressors: Turn Waste Energy into Savings for UK Workshops 2026

What if up to 94% of the energy used by your air compressor is converted into heat, much of which is simply wasted, potentially costing

The Ultimate Guide to Air Line Fittings: Types, Uses, and Maintenance for UK Workshops

Did you know that poor quality air line fittings can cause up to 30% energy loss in compressed air systems, costing UK workshops thousands in