Are you struggling to find a small compressor that fits your specific needs without breaking the bank?

What You Will Learn

- Understanding compressor size and capacity

- Types of small compressors and power sources

- Key technical specifications: pressure, airflow, tank size

- Choosing the right compressor for your application

- Maintenance and aftercare essentials

- Frequently asked questions about small compressors

Introduction

Choosing the right small compressor is crucial for efficiency, cost savings, and the success of your projects. Whether you’re a DIY enthusiast, a tradesperson, or running a small workshop anywhere in the UK, understanding how to select the perfect compressor can be confusing. This guide will simplify the process, helping you make an informed decision that meets your specific needs.

What Is a Small Compressor?

A small compressor is a compact, portable air compressor designed to deliver compressed air for light to medium-duty tasks. Despite their size, these compressors are powerful enough to handle a variety of jobs, making them ideal for both professional tradespeople and DIY enthusiasts across the UK.

Typical Uses and Applications

Small compressors are versatile tools used in many applications, including:

- Powering pneumatic tools such as nail guns, impact wrenches, and spray guns

- Inflating tyres, sports equipment, and air mattresses

- Spray painting and cleaning surfaces

- Light industrial and agricultural tasks

- Home workshops and small-scale construction projects

Their portability and ease of use make them particularly popular for on-site work and in environments where space is limited.

Why Size Matters

Choosing the right size compressor is essential to ensure efficiency and avoid unnecessary costs. An undersized compressor may not provide sufficient airflow or pressure, leading to tool underperformance and increased wear. Conversely, an oversized compressor can waste energy and increase upfront costs.

The correct size depends on your specific air consumption needs, typically measured in cubic feet per minute (CFM) and pressure requirements in bar or pounds per square inch (PSI). Understanding these factors helps you select a compressor that matches your tools and usage patterns perfectly.

Types of Small Compressors

Small compressors come in different types, each suited to particular needs and environments.

Electric Compressors (110V and 230V)

Electric small compressors are popular for indoor use due to their quiet operation and zero emissions. They are available in standard UK voltages (110V and 230V) and are ideal for workshops, garages, and home use. Models often feature oil-free designs for low maintenance and quieter running, typically around 65-72 dB.

Petrol and Diesel Compressors

Petrol and diesel small compressors offer greater mobility and power, making them suitable for outdoor and remote job sites where electricity is unavailable. Diesel models, in particular, are designed to meet stringent EU Stage V emissions standards and are often used in construction and agricultural settings.

Direct-Drive vs Belt-Drive Models

- Direct-Drive Compressors: The motor is directly connected to the compressor pump, resulting in a compact design with fewer moving parts. These are generally quieter and require less maintenance, making them suitable for smaller, portable compressors.

- Belt-Drive Compressors: The motor drives the compressor pump via a belt, allowing the motor and pump to run at different speeds. Belt-drive models tend to be larger, quieter under load, and better suited for continuous heavy-duty use.

Key Specifications to Consider

Pressure (Bar and PSI)

Pressure indicates the force of the compressed air and is crucial for tool compatibility. Most pneumatic tools require pressures between 70 and 120 PSI (approximately 5 to 8 bar). Always check your tool’s specifications to ensure the compressor can deliver the required pressure.

Airflow (CFM and L/min)

Airflow measures the volume of air the compressor can supply, typically in cubic feet per minute (CFM) or litres per minute (L/min). Tools with continuous airflow needs, like spray guns, require higher CFM ratings, while intermittent tools like nail guns need less.

Tank Size and Its Impact

The tank size, measured in litres, affects how long the compressor can supply air before the motor needs to run again. Larger tanks provide smoother airflow and longer run times but add weight and bulk. Small compressors usually have tanks ranging from 9 to 60 litres, balancing portability and capacity.

Noise Levels and Portability

Noise levels vary by model and power source, with electric compressors generally quieter (around 65-72 dB) than petrol or diesel models (which can exceed 75 dB). Portability is also key; lightweight models are easier to move around job sites or workshops.

How to Choose the Right Small Compressor for Your Needs

Matching Compressor Specs to Your Tools

Identify the pressure and airflow requirements of your pneumatic tools. Ensure the compressor’s maximum pressure and CFM ratings meet or exceed these needs to maintain tool performance and longevity.

Frequency and Duration of Use

For occasional or light use, a small compressor with a modest tank and airflow may suffice. For frequent or continuous operation, select a model with a larger tank and higher CFM to avoid overheating and downtime.

Indoor vs Outdoor Use Considerations

Electric compressors are best suited for indoor or noise-sensitive environments due to their quiet, emission-free operation. Petrol and diesel compressors offer portability and power for outdoor or remote locations, but are noisier and require more maintenance.

Maintenance Tips for Small Compressors

Regular Checks and Servicing

Routine maintenance includes checking oil levels (if applicable), cleaning or replacing air filters, draining condensate from the tank, and inspecting hoses and fittings to prevent leaks and ensure safety.

Spare Parts and Lubricants

Using genuine spare parts and recommended lubricants helps maintain compressor efficiency and prolongs its lifespan. Compressed Air Systems UK offers expert servicing and next-day delivery of parts across the UK.

Troubleshooting Common Issues

Common problems include pressure loss, excessive noise, and motor overheating. Regular maintenance and prompt servicing can prevent these issues and keep your compressor running smoothly.

Conclusion

Selecting the right small compressor is essential to ensure your tools perform efficiently, reduce energy waste, and avoid costly downtime. By understanding key factors such as compressor size, power source, and technical specifications, you can confidently choose a model that perfectly suits your needs, whether for DIY projects, professional workshops, or on-site work. Regular maintenance and expert support further guarantee your compressor’s longevity and reliability.

At Compressed Air Systems UK, we’re dedicated to helping you find the ideal small compressor tailored to your requirements, backed by quality products and exceptional service.

Ready to Find Your Perfect Small Compressor?

Join hundreds of satisfied customers across the UK who trust Compressed Air Systems UK for reliable, efficient, and portable compressed air solutions. Whether you need expert advice, a free quote, or fast delivery, our team is here to help.

Get in touch today and experience the difference!

Frequently Asked Questions About Small Compressors

Choosing the right small compressor can raise a number of questions, especially if you’re new to compressed air systems. To help you make an informed decision, we’ve compiled answers to some of the most common queries we receive from customers across the UK. If you don’t find the answer you’re looking for, our expert team at Compressed Air Systems UK is always ready to assist.

Small compressors are versatile tools used to power pneumatic equipment such as nail guns, impact wrenches, spray guns, and for inflating tyres or sports equipment. They are ideal for light to medium-duty tasks in workshops, construction sites, and home projects.

Choosing the right size depends on the air pressure (bar or PSI) and airflow (CFM or L/min) your tools require. It’s important to select a compressor that can meet or exceed these specifications to ensure efficient and reliable operation.

Electric compressors are quieter, require less maintenance, and are suitable for indoor use where a power supply is available. Petrol compressors offer greater mobility and power for outdoor or remote locations, but tend to be noisier and require regular servicing.

Noise levels vary by model and power source. Electric compressors typically operate between 65-72 decibels (dB), while petrol and diesel models can be louder, often exceeding 75 dB. Silenced models are available for quieter operation.

Regular servicing is essential to maintain performance and extend the lifespan of your compressor. We recommend checking oil levels (if applicable), cleaning filters, and draining condensate after every use, with a full service at least once a year or as advised by the manufacturer.

Yes, we offer flexible hire options for small compressors, ideal for short-term projects or trial periods before purchase. Contact us to discuss availability and pricing.

Common spare parts include air filters, pressure switches, hoses, and lubricants. Using genuine parts ensures optimal performance and longevity. Our team can advise on the right accessories for your model.

We provide fast delivery across the UK, often dispatching in-stock compressors the next working day. Contact us for specific delivery times based on your location and order.

Explore More of Our Articles

The Ultimate Guide to Diesel Air Compressors: Power, Portability, and Performance for UK Applications

The Ultimate Guide to Diesel Air Compressors: Power, Portability, and Performance for UK Applications Everything UK professionals need to know about diesel air compressors —

The Ultimate Guide to Petrol Compressors: Portable Power for UK Sites and Workshops

The Ultimate Guide to Petrol Compressors: Portable Power for UK Sites and Workshops Everything UK tradespeople and site managers need to know about petrol compressors

What Size Air Compressor Do You Need? (CFM, Tank Size & Power Guide UK)

What Size Air Compressor Do I Need? Use this UK-focused guide to calculate CFM, choose the right tank size, and match voltage & duty cycle—then

Explore Our Complete Air Compressor Range

Shop the Full Tanair Air Compressor Range Compare portable direct drive, belt-driven workshop and energy-saving VSD compressors — then buy online, call for instant advice,

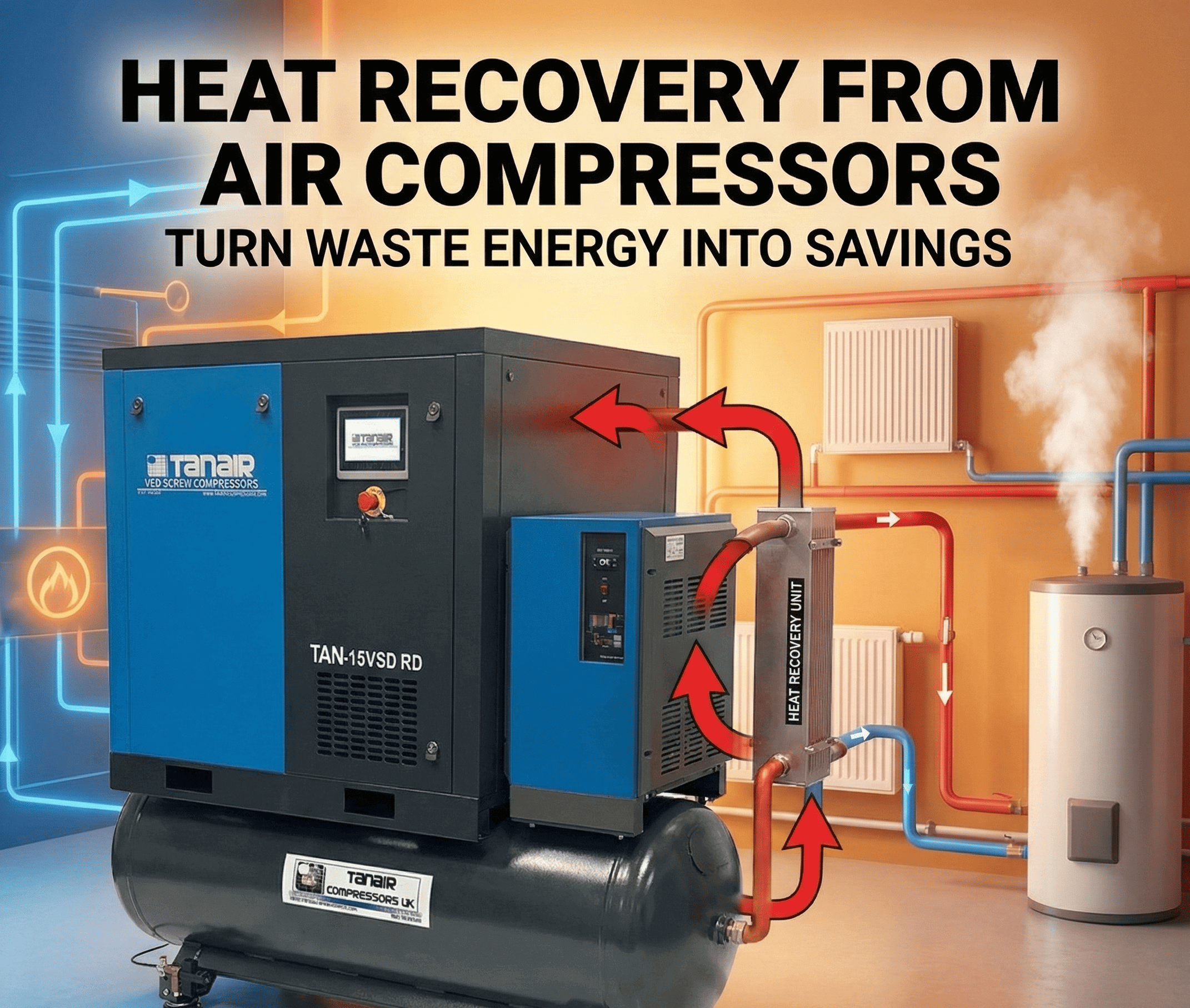

Heat Recovery from Air Compressors: Turn Waste Energy into Savings for UK Workshops 2026

What if up to 94% of the energy used by your air compressor is converted into heat, much of which is simply wasted, potentially costing

The Benefits of Deep Cleaning Your Compressed Air System

Did you know that accumulated contaminants in compressed air systems can cause up to 30% energy waste, adding thousands to annual electricity costs for UK