Did you know that a single hour of compressor downtime in a mid-sized manufacturing plant can cost up to £10,000 in lost production alone? In Tamworth’s bustling industrial heartland, where factories hum around the clock, such breakdowns are not just inconvenient; they threaten the very viability of operations.

Key Areas We Will Cover

- The hidden financial toll: Direct repair costs and lost revenue streams

- Production ripple effects: How one failure cascades through supply chains

- Tamworth’s unique vulnerabilities: Local sector insights and real-world examples

- Proactive safeguards: Maintenance strategies to slash downtime risks

- Rapid response solutions: Emergency support tailored for Tamworth businesses

Introduction

In Tamworth’s industrial sector, air compressors are essential components in manufacturing, engineering, and logistics operations. These systems support processes ranging from automotive assembly to food processing. Compressor downtime, however, extends beyond temporary interruptions, affecting profitability, supply chains, and operational efficiency.

The Financial Impact of Compressor Breakdowns

Compressor failures incur both direct and indirect costs, often exceeding initial repair expenses due to operational losses.

Direct Repair and Replacement Costs

Repair costs for industrial air compressors vary by issue and unit size. Minor leaks typically cost £150–£300 to address, while motor repairs range from £500–£1,500. Major overhauls can exceed £3,000, including parts and labour. Full replacement of rotary screw compressors, common in heavy-duty applications, often surpasses £10,000, incorporating installation and associated downtime.

Energy inefficiency further amplifies expenses. Air leaks account for 20–30% of compressed air waste in typical systems, leading to increased electricity consumption. Energy represents 70–80% of a compressor’s lifecycle costs.

- Leak repairs: £150–£300

- Motor repairs: £500–£1,500

- Full overhauls: £3,000+

Proactive audits, costing £500–£1,000 biannually, can identify issues early and reduce long-term expenditure.

Lost Production Costs

Unplanned downtime in UK manufacturing averages approximately £5,000 per hour, though figures vary widely by facility size and sector, ranging from under £1,000 to over £50,000 in larger operations. Compressor-related stoppages contribute significantly, given that compressed air systems support up to 70% of manufacturing processes.

For a mid-sized plant, one hour of downtime may result in £5,000–£20,000 in lost output, depending on production value. Extended incidents, such as a four-hour shutdown, could therefore approach £20,000–£80,000, factoring in idle labour (e.g., £300 per hour for a team of 20 at £15 per hour) and recovery efforts.

Production and Supply Chain Effects

Downtime initiates cascading disruptions within and beyond the affected facility.

Operational and Workforce Impacts

In just-in-time manufacturing environments, compressor failure halts pneumatic tools and automation, idling staff and delaying output. Unplanned stoppages can reduce overall equipment effectiveness (OEE) by 10–20%. Recovery often requires overtime, adding £1,000–£5,000 per incident, while rushed restarts may increase defect rates and rework costs.

Supply Chain Disruptions

Tamworth’s industries, including engineering and food processing, integrate with regional networks in Coventry, Birmingham, and Leicester. Equipment failures contribute to broader UK manufacturing downtime costs, estimated at £80–£180 billion annually across all causes. Specific compressor-related supply disruptions lack precise national quantification but disproportionately affect SMEs with limited backup systems.

Tamworth’s Industrial Context

Tamworth serves as a Midlands industrial centre with established manufacturing in metals, food processing, and logistics. The area supports numerous sites and contributes to regional economic output, though exact figures such as “over 200 manufacturing facilities” or “£2 billion annual contribution” remain unverified in public data.

Local factors, including reliance on established equipment and energy cost pressures, heighten vulnerability to breakdowns. Post-Brexit supply challenges and net-zero targets further emphasise the need for efficient systems, as inefficient compressors increase both bills and emissions risks.

Proactive Mitigation Strategies

Evidence-based maintenance reduces failure risks substantially.

Maintenance Practices

Servicing every 2,000 operating hours or every six months can decrease breakdown rates by 40–50%. Predictive technologies, such as IoT sensors, reduce unplanned downtime by 30–50%.

- Biannual audits: £500–£1,000

- Ultrasonic leak detection: Identifies 20–30% air losses

- Variable-speed drives: Yield 20–35% energy savings

Redundancy and Training

Backup compressor installations, costing £5,000–£15,000 initially, enhance resilience. Staff training on fault detection supports early intervention.

Rapid Response Solutions for Tamworth Businesses

When prevention falls short, swift intervention is key. For Tamworth’s industrial players, 24/7 emergency air compressor breakdown assistance ensures minimal disruption. Local specialists like Compressed Air Systems UK deploy engineers within hours, restoring operations and capping losses at hours, not days. This service, tailored to the Midlands’ pace, includes on-site diagnostics and hire units to bridge gaps, proving invaluable for high-stakes environments.

Conclusion

Compressor downtime in Tamworth’s industrial sector entails repair costs, production losses, and supply chain impacts that collectively threaten competitiveness. UK averages indicate £5,000+ per hour in downtime expenses, underscoring the value of preventive maintenance and contingency planning. By adopting these measures, businesses can strengthen operational reliability and support sustained growth.

Secure Your Operations Today: Act Now Against Downtime

Do not let a compressor failure derail your Tamworth business. Contact Tan Air Compressors for a free audit and fortify your setup with expert 24/7 support. Schedule your consultation and reclaim productivity, one reliable breath at a time.

Frequently Asked Questions

Air leaks (20–30% waste), motor wear, and filter neglect, exacerbated by intensive usage.

Calculate hourly output value (£5,000–£20,000 typical), add idle labour (£300+ per hour for small teams), and include overtime (£1,000+). Conduct production audits for accuracy.

Yes, with response times under four hours, potentially preventing losses exceeding £20,000 per incident.

Every 2,000 hours or six months, whichever occurs first, to reduce risks by 40–50% and extend equipment life.

Explore More of Our Articles

The Ultimate Guide to Diesel Air Compressors: Power, Portability, and Performance for UK Applications

The Ultimate Guide to Diesel Air Compressors: Power, Portability, and Performance for UK Applications Everything UK professionals need to know about diesel air compressors —

The Ultimate Guide to Petrol Compressors: Portable Power for UK Sites and Workshops

The Ultimate Guide to Petrol Compressors: Portable Power for UK Sites and Workshops Everything UK tradespeople and site managers need to know about petrol compressors

Explore Our Complete Air Compressor Range

Shop the Full Tanair Air Compressor Range Compare portable direct drive, belt-driven workshop and energy-saving VSD compressors — then buy online, call for instant advice,

What Size Air Compressor Do You Need? (CFM, Tank Size & Power Guide UK)

What Size Air Compressor Do I Need? Use this UK-focused guide to calculate CFM, choose the right tank size, and match voltage & duty cycle—then

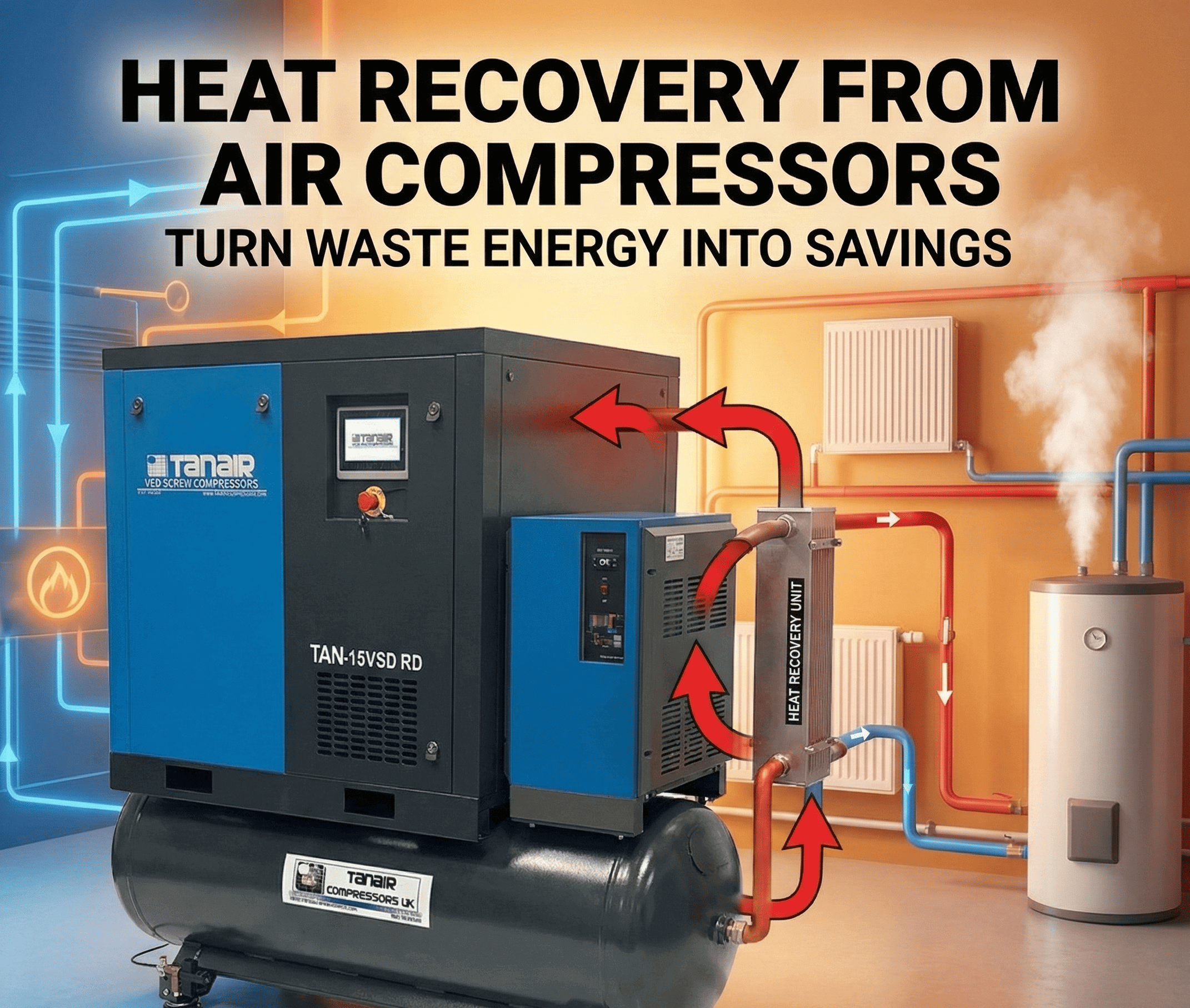

Heat Recovery from Air Compressors: Turn Waste Energy into Savings for UK Workshops 2026

What if up to 94% of the energy used by your air compressor is converted into heat, much of which is simply wasted, potentially costing

The Ultimate Guide to Air Line Fittings: Types, Uses, and Maintenance for UK Workshops

Did you know that poor quality air line fittings can cause up to 30% energy loss in compressed air systems, costing UK workshops thousands in