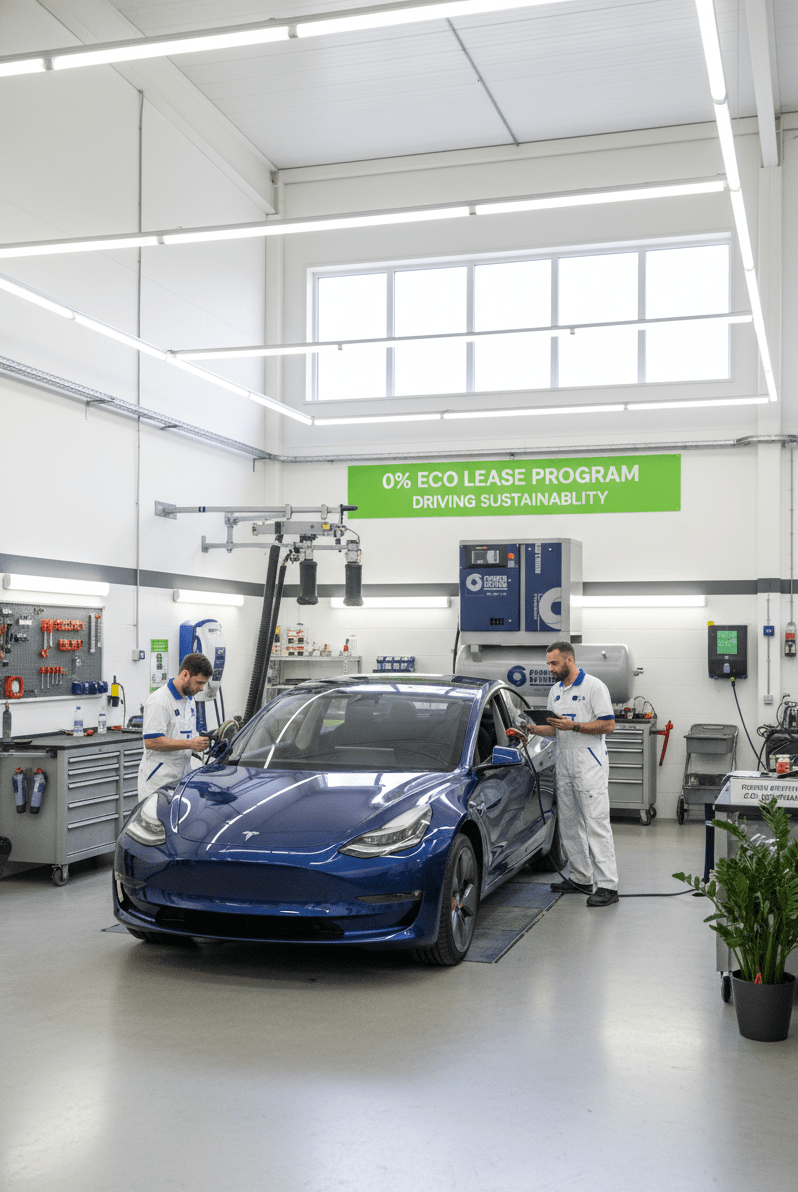

Did you know that adopting energy-efficient practices in car body repairs can cut costs, boost your reputation, and reduce your environmental footprint? With the launch of our 0% ECO lease for energy-efficient air compressors, now is the perfect time for car body workshops to embrace sustainability and modernise operations.

Key Areas We Will Cover

- The ARIES Standard and its role in promoting sustainable vehicle repairs

- Insurance incentives driving eco-friendly practices

- The PAS 2060 Standard for carbon neutrality

- Practical energy-saving practices for workshops

- Benefits of adopting sustainable repair methods

- How our 0% ECO lease can transform your workshop

Introduction

As the automotive repair industry evolves, sustainability is becoming a cornerstone of modern car body workshops. With no comprehensive UK government policy on energy-efficient car accident repairs, industry-led initiatives like the ARIES Standard and incentives from insurers such as Allianz are paving the way. Our new 0% ECO lease for variable speed air compressors offers workshops an affordable way to upgrade, reduce costs, and align with eco-conscious standards. This article explores how these initiatives and practices can help your workshop thrive in an increasingly sustainable market.

The ARIES Standard: A Framework for Sustainable Repairs

The ARIES Standard is an industry-led initiative designed to reduce carbon emissions in vehicle accident repairs. It provides a structured approach for workshops to measure and minimise their environmental impact. By adopting this standard, businesses can:

- Track energy consumption and emissions

- Implement sustainable practices across operations

- Demonstrate a commitment to environmental responsibility

This framework is critical for workshops aiming to stay competitive in a market that increasingly values sustainability.

Insurance Incentives: Rewarding Eco-Friendly Repairs

Progressive insurers like Allianz are encouraging sustainable practices by offering:

- Energy Credits: Financial support to offset the costs of adopting energy-efficient equipment, such as our variable-speed air compressors.

- Lower Excess Fees: Reduced fees for customers who choose approved sustainable repairers.

These incentives not only make financial sense but also attract eco-conscious customers, enhancing your workshop’s appeal.

PAS 2060: Achieving Carbon Neutrality

The PAS 2060 Standard is a globally recognised benchmark for carbon neutrality. Repair groups like The Vella Group have adopted it to achieve sustainability across all their sites. By aligning with PAS 2060, workshops can:

- Offset carbon emissions through verified schemes

- Enhance credibility with customers and insurers

- Contribute to a greener industry

Energy-Saving Practices for Car Body Workshops

Implementing sustainable practices is easier than you might think. Here are actionable steps to reduce your workshop’s environmental footprint:

Equipment Upgrades

- LED Lighting: Switching to energy-efficient LED lights can reduce electricity consumption by up to 50%.

- Heat-Recycling Spray Booths: These innovative booths reuse heat, cutting energy costs significantly.

- Energy-Efficient Air Compressors: Our 0% ECO lease for variable speed compressors provides access to cutting-edge technology that optimises energy use over its lifecycle, offering fixed monthly payments and potential tax benefits.

Material Use

- Single-Coat Paints and Infrared Cure Primers: These reduce bake times in spray booths, saving energy.

- Water-Based Paints: Transitioning from solvent-based to water-based paints lowers volatile organic compound (VOC) emissions, improving air quality.

- Repair Over Replacement: Prioritising part repairs and using recycled or “green” components minimises waste.

Waste Management

- Recycling Practices: Implement robust systems for recycling materials like metal and plastic.

- Chemical Disposal: Safely store and dispose of paints and chemicals to reduce environmental harm.

Benefits of Sustainable Car Body Repairs

Adopting these practices, paired with equipment like our energy-efficient air compressors, offers multiple advantages:

- Cost Savings: Energy-efficient equipment and processes can lower utility bills and qualify workshops for tax incentives, with lease payments potentially 100% tax-deductible.

- Enhanced Reputation: Eco-conscious practices attract customers and insurers, boosting brand loyalty.

- Environmental Impact: Reducing energy use and emissions contributes to a healthier planet.

Consult a tax advisor for specific eligibility and implications.

No posts found!

Our 0% ECO Lease: A Game-Changer for Workshops

Our 0% ECO lease makes upgrading to energy-efficient variable speed air compressors affordable. With no upfront costs, workshops can:

- Access state-of-the-art technology without impacting cash flow

- Benefit from fixed monthly payments over 12 or 24 months, protecting against interest rate fluctuations

- Enjoy a full equipment guarantee for the lease duration

- Explore flexible end-of-term options, including potential ownership transfer for a nominal fee

- Reduce energy consumption and align with ARIES and PAS 2060 standards

This initiative is designed to help car body workshops modernise while meeting the growing demand for sustainable repairs.

Conclusion

Sustainability is no longer optional for car body workshops; it’s a competitive advantage. By adopting the ARIES Standard, leveraging insurance incentives, and implementing energy-saving practices, workshops can reduce costs, enhance their reputation, and contribute to a greener future. Our 0% ECO lease for variable speed air compressors makes it easier than ever to get started.

Take the Next Step Towards Sustainability

Ready to transform your workshop? Contact us today to learn how our 0% ECO lease can help you upgrade to sustainable standards and drive long-term success.

Frequently Asked Questions

Curious about how sustainable practices and our 0% ECO lease can benefit your workshop? Below, we answer common questions to help you make an informed decision.

The ARIES Standard is an industry-led framework that guides car body workshops in reducing carbon emissions and adopting sustainable practices.

Insurers like Allianz offer energy credits and lower excess fees for customers who choose workshops with approved sustainable practices, helping offset costs.

PAS 2060 is a global standard for achieving carbon neutrality, adopted by repair groups to offset emissions and enhance sustainability.

Our 0% ECO lease allows workshops to acquire energy-efficient variable speed air compressors with no upfront costs. Fixed monthly payments are made over 12 or 24 months, with potential tax benefits and flexible end-of-term options, including ownership transfer for a nominal fee.

Explore More of Our Articles

The Ultimate Guide to Diesel Air Compressors: Power, Portability, and Performance for UK Applications

The Ultimate Guide to Diesel Air Compressors: Power, Portability, and Performance for UK Applications Everything UK professionals need to know about diesel air compressors —

The Ultimate Guide to Petrol Compressors: Portable Power for UK Sites and Workshops

The Ultimate Guide to Petrol Compressors: Portable Power for UK Sites and Workshops Everything UK tradespeople and site managers need to know about petrol compressors

Explore Our Complete Air Compressor Range

Shop the Full Tanair Air Compressor Range Compare portable direct drive, belt-driven workshop and energy-saving VSD compressors — then buy online, call for instant advice,

What Size Air Compressor Do You Need? (CFM, Tank Size & Power Guide UK)

What Size Air Compressor Do I Need? Use this UK-focused guide to calculate CFM, choose the right tank size, and match voltage & duty cycle—then

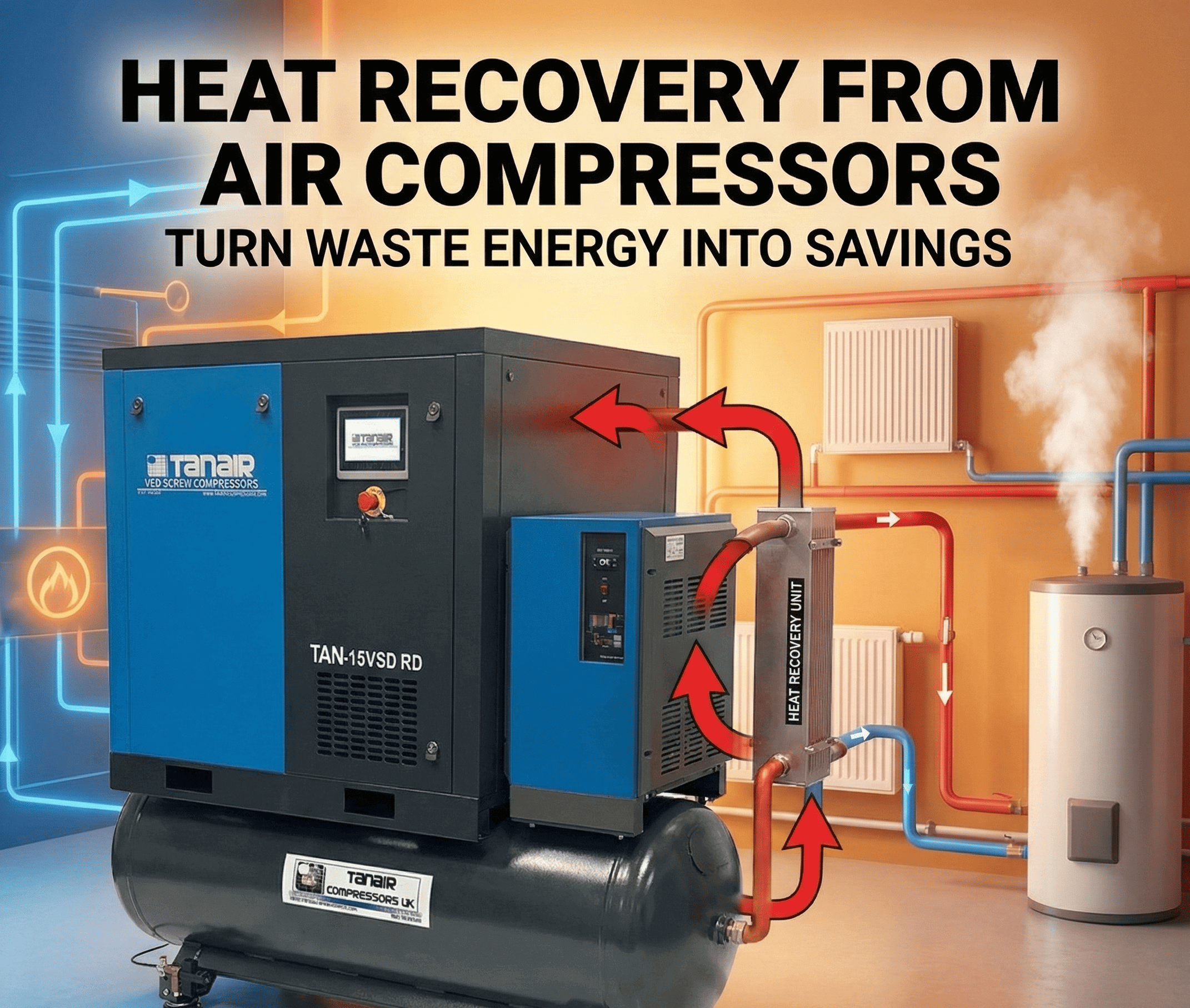

Heat Recovery from Air Compressors: Turn Waste Energy into Savings for UK Workshops 2026

What if up to 94% of the energy used by your air compressor is converted into heat, much of which is simply wasted, potentially costing

The Ultimate Guide to Air Line Fittings: Types, Uses, and Maintenance for UK Workshops

Did you know that poor quality air line fittings can cause up to 30% energy loss in compressed air systems, costing UK workshops thousands in