What if up to 94% of the energy used by your air compressor is converted into heat, much of which is simply wasted, potentially costing UK workshops thousands in lost heating opportunities each year?

“Heat recovery is not just an add-on; it is a game-changer for energy efficiency and cost reduction in compressed air systems.”

Key Areas We Will Cover

- How heat recovery works in compressed air systems

- The impressive energy and cost savings potential for UK businesses

- Types of heat recovery systems and compatibility with modern compressors

- Real-world applications in workshops, garages, and industrial settings

- Step-by-step guide to implementing heat recovery

- Top compressor models suited for heat recovery in 2026

- Emerging trends and UK regulations driving adoption

Introduction

Heat recovery from air compressors captures and reuses the substantial waste heat generated during compression, turning it into a valuable resource for heating water, spaces, or processes. In the UK, where business energy prices hover around 22 to 24 pence per kWh in January 2026, and net-zero targets demand greater efficiency, this technology offers workshops a practical way to slash costs and reduce carbon footprints. This guide delves into the mechanics, benefits, and implementation of heat recovery, providing actionable insights tailored to British workshops and drawing on the latest industry developments to help you optimise your compressed air setup.

Understanding Heat Recovery in Compressed Air Systems

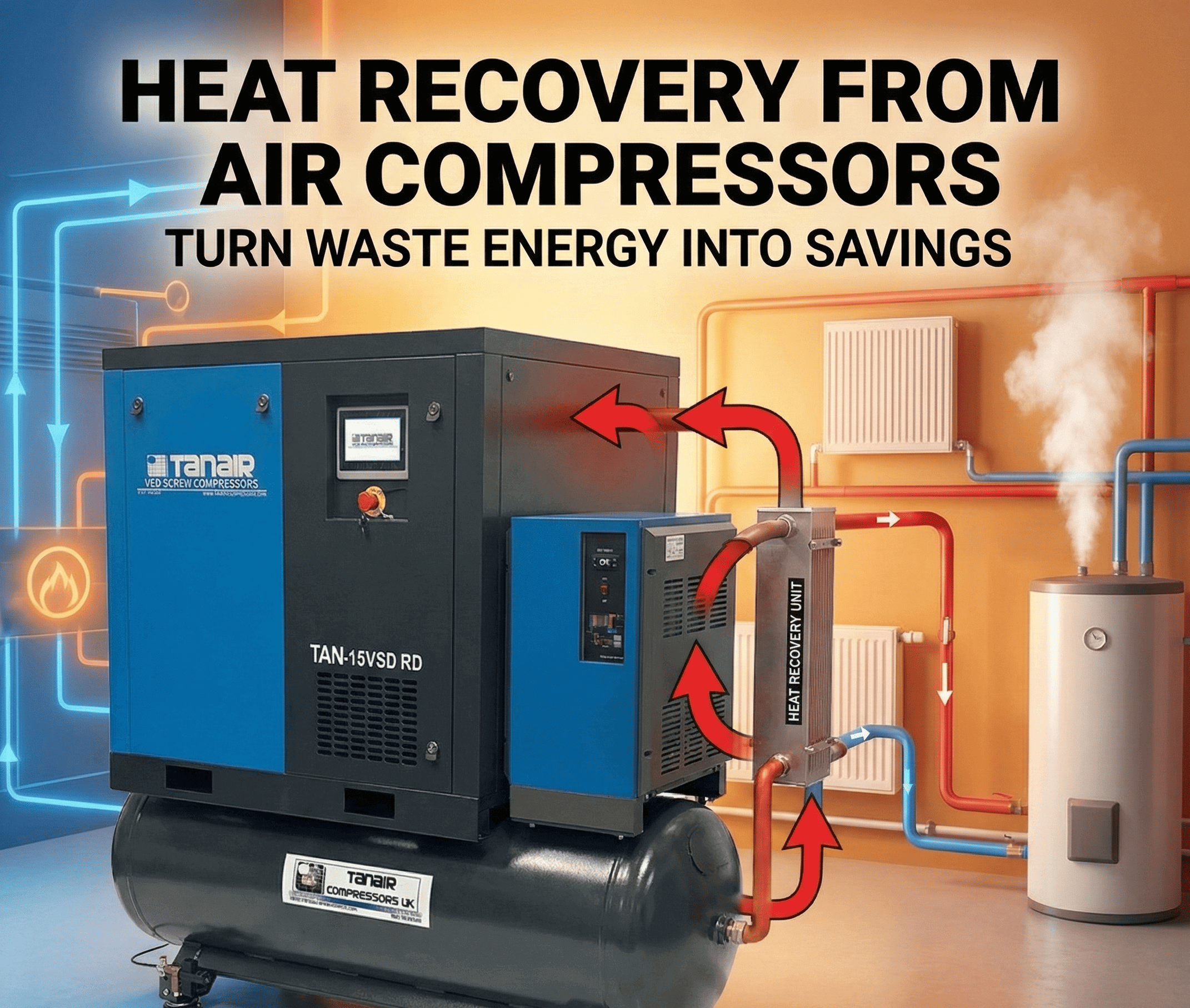

Compressed air systems are essential in UK workshops for powering tools, machinery, and processes, but they are notoriously inefficient in energy use. A typical air compressor converts up to 94% of its electrical input into heat, with only a small fraction actually used for air compression. Heat recovery systems harness this byproduct, redirecting it to productive ends rather than venting it away.

How Does Heat Recovery Work?

The process begins at the compressor’s cooling stage, where heat exchangers capture excess warmth from the oil, air, or water coolant. This captured heat can then be transferred via ducts for air heating or through pipes for water warming. Modern systems ensure no contamination risks, using barriers to separate compressed air from recovery fluids. For instance, in a variable-speed drive compressor, the variable output aligns heat generation with demand, making recovery more efficient.

Why It Matters for UK Workshops

With UK business electricity rates at approximately 24 pence per kWh for small to medium workshops in 2026, wasted heat equates to wasted money. Implementing recovery can align with government incentives under schemes like the Enhanced Capital Allowance, supporting net-zero ambitions while delivering immediate financial relief amid volatile energy markets.

Benefits of Heat Recovery for UK Businesses

Adopting heat recovery transforms operational overheads into opportunities, particularly in energy-intensive sectors.

- Energy Cost Reductions: Recover up to 94% of heat, potentially cutting heating bills by 20 to 50% depending on usage.

- Environmental Impact: Lower CO2 emissions by substituting fossil fuel heating, aiding compliance with UK net-zero targets by 2050.

- Operational Efficiency: Cooler-running compressors extend equipment life and reduce maintenance needs.

- Quick Return on Investment: Payback periods often fall within 1 to 3 years, especially with rising energy costs.

Real-world examples from UK manufacturers show annual savings exceeding £10,000 for mid-sized operations, highlighting the technology’s viability even for smaller workshops.

Types of Heat Recovery Systems

Heat recovery solutions vary to suit different compressor types and workshop needs.

Air-to-Air Recovery

This system ducts hot exhaust air directly into workshop spaces for heating. It is simple, cost-effective, and ideal for garages facing cold UK winters, with temperatures reaching up to 90°C.

Air-to-Water Recovery

Heat is transferred to water for uses like process heating or domestic hot water. More versatile for industrial applications, it achieves higher efficiency in water-cooled compressors.

Integrated vs Retrofit Options

New compressors often include built-in recovery features, while retrofits adapt existing units with add-on exchangers. For UK workshops, retrofits start from £1,000 to £5,000, depending on scale.

Calculating Your Potential Savings

To estimate benefits, use this formula: Annual savings = (Compressor power in kW) × (Operating hours per year) × (Recovery efficiency, e.g., 80%) × (Energy price per kWh).

For example, a 15 kW compressor running 2,000 hours annually at 80% recovery efficiency and 24 pence per kWh could save around £5,760 per year. Adjust for your setup using our free energy audit service.

Compressor Size | Annual Hours | Recovery Rate | Energy Price (p/kWh) | Estimated Savings |

10 kW (Small Workshop) | 1,500 | 70% | 24 | £2,520 |

20 kW (Medium Garage) | 2,000 | 80% | 24 | £7,680 |

50 kW (Industrial) | 3,000 | 90% | 22 | £29,700 |

These figures underscore the scalability for UK businesses.

Real-World Applications in UK Workshops

In automotive garages, recovered heat warms spray booths; in manufacturing, it preheats processes. Home DIY setups benefit from space heating, reducing reliance on separate boilers. Case studies from Midlands factories show 30% energy bill reductions, proving efficacy in damp, variable UK climates.

Best Compressors for Heat Recovery in 2026

Our energy-efficient range at Compressed Air Systems UK provides an excellent foundation for heat recovery.

- TAN10-VSD/10 Floorpack (415 Volt): This variable-speed model delivers up to 41 CFM and is optimised for heat output, making it ideal for retrofit recovery in small workshops.

- Power Systems NOBEL Series (e.g., NOBEL 2210 PM): Permanent magnet motors ensure high efficiency, compatible with air-to-water systems for medium-scale operations.

These models integrate seamlessly with third-party recovery kits, and our team can advise on custom setups.

Step-by-Step Guide to Implementing Heat Recovery

- Assess Your System: Conduct an energy audit to measure heat output and identify uses.

- Choose the Type: Select air-to-air for simplicity or air-to-water for versatility.

- Install Equipment: Work with certified engineers; costs range from £2,000 for basic setups.

- Monitor and Maintain: Use IoT sensors for ongoing optimisation.

- Claim Incentives: Apply for UK grants to offset initial outlay.

Professional installation ensures compliance with British standards like BS EN 378.

2026 Trends in Heat Recovery

Looking ahead, smart IoT-enabled systems will predict and optimise heat capture, integrating with renewables like solar for hybrid efficiency. Bio-based materials in exchangers will enhance sustainability, and high-flow designs could boost recovery rates by 20%. With UK energy policies pushing for net-zero, expect more incentives for adopters.

Conclusion

Heat recovery from air compressors offers UK workshops a straightforward path to substantial savings, enhanced efficiency, and environmental responsibility. By capturing waste heat, businesses can minimise costs while aligning with 2026 sustainability goals. This guide equips you with the knowledge to evaluate and implement solutions tailored to your needs.

Unlock Your Heat Recovery Potential Today

Do not let valuable energy go to waste. Contact Compressed Air Systems UK for a free energy audit and explore our compatible compressor range. Visit our website or call 0121 753 3330 to get started and transform your workshop’s efficiency.

Explore More of Our Articles

The Benefits of Deep Cleaning Your Compressed Air System

Did you know that accumulated contaminants in compressed air systems can cause up to 30% energy waste, adding thousands to annual electricity costs for UK

The Ultimate Guide to Air Line Fittings: Types, Uses, and Maintenance for UK Workshops

Did you know that poor quality air line fittings can cause up to 30% energy loss in compressed air systems, costing UK workshops thousands in

Wall-Mounted Air Compressors: The Ultimate Space-Saving Guide for UK Garages in 2025/26

Did you know that the average UK garage loses up to 2 square metres of valuable floor space to a traditional air compressor – enough

The True Cost of Compressor Downtime in Tamworth’s Industrial Sector

Did you know that a single hour of compressor downtime in a mid-sized manufacturing plant can cost up to £10,000 in lost production alone? In

Air Compressor Kits vs Standalone Tools: Which Setup Saves You Time and Money in the UK?

Did you know that over 70% of UK DIY enthusiasts end up spending an extra £150 or more piecing together mismatched air tools that fail

Energy-Efficient Car Body Repairs: Driving Sustainability with a 0% ECO Lease

Did you know that adopting energy-efficient practices in car body repairs can cut costs, boost your reputation, and reduce your environmental footprint? With the launch