“Did you know that air hoses are the unsung heroes powering everything from automotive repair shops to large-scale manufacturing plants? Without them, many industries would grind to a halt.”

How do air hoses impact diverse industries?

What pneumatic tools rely on air hoses daily?

Why choosing the right air hose matters for operational efficiency.

Key Areas to Cover

- Overview of air hose applications across industries

- Air hoses in automotive workshops

- Air hoses in manufacturing plants

- Air hoses in food and beverage processing

- Air hoses in construction sites

- Air hoses in welding and metal fabrication

- Examples of pneumatic tools and machines powered by air hoses

- Benefits of using air hoses in industrial settings

Introduction

Air hoses are critical components in numerous industries, enabling the transfer of compressed air to power pneumatic tools and machinery. Their durability, flexibility, and ability to withstand high pressure make them indispensable in automotive workshops, manufacturing plants, food processing, construction, and welding industries. This article explores the vital role air hoses play across these sectors and highlights key tools and applications that depend on them.

No posts found!

Air Hoses in Automotive Workshops

In automotive workshops, air hoses play a crucial role in powering a variety of pneumatic tools that speed up repairs and maintenance tasks. Common applications include air impact wrenches used for quickly removing and fitting bolts, spray guns for paintwork, tyre inflation equipment, and pneumatic lifts that raise vehicles safely and efficiently.

The fast-paced nature of garage environments demands air hoses that are both highly flexible and capable of withstanding high pressure. Flexibility ensures ease of movement around vehicles and tight spaces, while pressure resistance guarantees consistent performance without risk of hose failure.

Typical tools powered by air hoses in automotive workshops include air ratchets, impact wrenches, and spray paint guns, all of which rely on a steady and reliable air supply to function optimally.

Air Hoses in Manufacturing Plants

Manufacturing plants depend heavily on air hoses to keep assembly lines and automated processes running smoothly. Air hoses supply compressed air to robotic tooling, packing machinery, and material handling equipment, enabling precise and efficient production.

Automation in manufacturing often involves pneumatic presses and robotic end-of-arm tooling, both of which require consistent air pressure to maintain accuracy and speed. Air hoses must therefore be durable and reliable to withstand continuous use in demanding industrial environments.

Examples of pneumatic tools powered by air hoses in manufacturing include robotic end-of-arm tooling, pneumatic presses, and packing machines, all essential for optimising productivity and maintaining high-quality standards.

Air Hoses in Food and Beverage Industry

In the food and beverage industry, air hoses are essential for transferring compressed air used in cleaning, packaging, and controlling pneumatic systems. These hoses must meet stringent hygiene and safety standards to prevent contamination and ensure product quality. As such, food-grade air hoses are specially designed from materials that comply with legal requirements and resist chemicals, temperature variations, and abrasion.

Typical applications include pneumatic filling equipment, spray guns for coating, and cleaning systems. Food-grade hoses are widely used in breweries, dairies, soft drink manufacturing, and other processing plants to safely transfer liquids and semi-solids while maintaining strict sanitary conditions.

Air Hoses in Construction Sites

Construction sites rely on air hoses to supply compressed air to a variety of pneumatic tools such as nail guns, jackhammers, sanders, and paint sprayers. These environments demand hoses that are not only durable but also resistant to abrasion, weather, and rough handling to withstand the harsh conditions on site.

Common tools powered by air hoses on construction sites include pneumatic nail guns, sanders, paint sprayers, and shot blasting equipment. The robustness and flexibility of air hoses ensure that workers can operate tools efficiently and safely, even in challenging outdoor settings.

Air Hoses in Welding and Metal Fabrication

In welding and metal fabrication, air hoses are indispensable for delivering compressed air to essential tools such as welding torches, plasma cutters, and grinding equipment. These applications require hoses that can withstand high temperatures and resist abrasion, ensuring safety and durability in demanding environments.

Heat-resistant and abrasion-resistant hose materials are critical to prevent damage from sparks, heat, and rough surfaces commonly encountered in welding and metalworking settings. Reliable air hoses help maintain consistent airflow, which is vital for the precision and effectiveness of welding and cutting operations.

Typical tools powered by air hoses in this sector include welding torches, plasma cutters, and air grinders, all of which depend on a steady, high-quality air supply to perform efficiently and safely.

No posts found!

Pneumatic Tools and Machines Powered by Air Hoses

Air hoses serve as the lifeline for a wide range of pneumatic tools and machines across industries. Some of the most common tools powered by compressed air include air impact wrenches, nail guns, sanders, paint guns, compressors, and blow guns.

By providing a consistent and powerful flow of compressed air, air hoses enable these tools to operate efficiently, delivering the force and precision required for various tasks. Moreover, air hoses contribute to safer working conditions by reducing the reliance on electrical power in potentially hazardous environments.

Benefits of Using Air Hoses in Industrial Settings

- Enhanced Flexibility and Mobility for Workers: Air hoses allow users to move freely and access hard-to-reach areas without being tethered by cables or heavy equipment.

- Consistent Air Pressure Delivery for Tool Performance: Reliable air hoses ensure that pneumatic tools receive steady air pressure, which is essential for optimal operation and longevity.

- Resistance to Wear, Chemicals, and Environmental Factors: Industrial air hoses are designed to withstand harsh conditions, including exposure to oils, chemicals, abrasion, and extreme temperatures.

- Cost-Effective and Reliable Power Transmission Solution: Compared to electrical alternatives, compressed air systems with quality hoses offer a durable and economical method of powering tools and machinery.

Conclusion

Air hoses are vital to the smooth operation of many industries, powering a wide range of pneumatic tools and machinery with reliability and efficiency. Whether in automotive repair, manufacturing, food processing, construction, or welding, choosing the right air hose is essential to ensure optimal performance, safety, and longevity.

Find Your Perfect Air Hose with Compressed Air Systems UK

Looking for reliable air hose solutions to power your business? Compressed Air Systems UK is your trusted partner for quality, durability, and expert support.

Explore our full range of air hose products and get in touch with our team today for tailored advice and unbeatable service.

No posts found!

Explore More of Our Articles

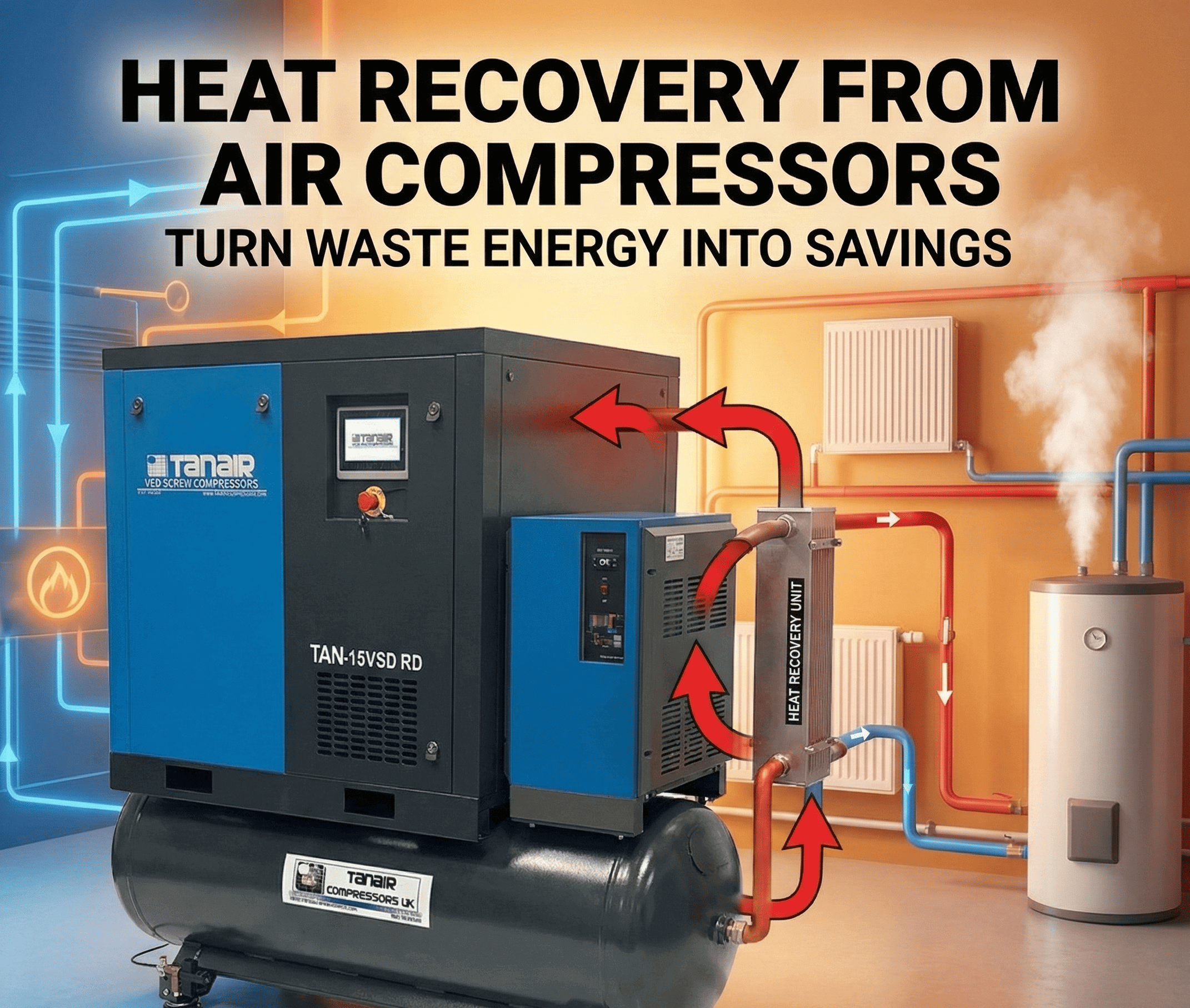

Heat Recovery from Air Compressors: Turn Waste Energy into Savings for UK Workshops 2026

What if up to 94% of the energy used by your air compressor is converted into heat, much of which is simply wasted, potentially costing

The Benefits of Deep Cleaning Your Compressed Air System

Did you know that accumulated contaminants in compressed air systems can cause up to 30% energy waste, adding thousands to annual electricity costs for UK

The Ultimate Guide to Air Line Fittings: Types, Uses, and Maintenance for UK Workshops

Did you know that poor quality air line fittings can cause up to 30% energy loss in compressed air systems, costing UK workshops thousands in

Wall-Mounted Air Compressors: The Ultimate Space-Saving Guide for UK Garages in 2025/26

Did you know that the average UK garage loses up to 2 square metres of valuable floor space to a traditional air compressor – enough

The True Cost of Compressor Downtime in Tamworth’s Industrial Sector

Did you know that a single hour of compressor downtime in a mid-sized manufacturing plant can cost up to £10,000 in lost production alone? In

Air Compressor Kits vs Standalone Tools: Which Setup Saves You Time and Money in the UK?

Did you know that over 70% of UK DIY enthusiasts end up spending an extra £150 or more piecing together mismatched air tools that fail