Did you know that inefficiencies in compressed air systems can account for up to 40% of wasted energy, costing UK businesses thousands annually?

“A well-executed air compressor audit can uncover savings equivalent to replacing an entire system, without the upfront cost.” – Energy Efficiency Consultant

Key Areas We Will Cover

- The purpose and benefits of air compressor audits

- Common inefficiencies in compressed air systems

- The audit process, including assessments and data logging

- ISO 11011 standards and their role in audits

- Energy-saving solutions and technologies

- Financial and environmental impacts of optimised systems

- How to choose a professional audit provider in the UK

- Frequently asked questions about air compressor audits

Compressed air systems are vital to industries across the UK, but inefficiencies such as leaks, over-pressurisation, and outdated equipment can inflate energy bills and carbon footprints. Air compressor audits identify these issues, offering actionable solutions to boost efficiency, reduce costs, and ensure compliance. This comprehensive guide explores how audits work, why they matter, and how to maximise their impact for your business.

Why Air Compressor Audits Matter

Air compressor audits are strategic evaluations designed to optimise system performance, cut energy waste, and extend equipment life. With energy costs rising, UK businesses face increasing pressure to operate sustainably and cost-effectively.

Benefits of Audits

- Cost Savings: Identify inefficiencies to reduce energy bills by up to 30%.

- Equipment Longevity: Detect issues like leaks or wear to prevent costly breakdowns.

- Environmental Impact: Lower energy use reduces CO2 emissions, supporting net-zero goals.

- Compliance: Ensure adherence to standards like ISO 11011 and ISO 50001 for energy management.

- Productivity: Optimised systems enhance operational reliability and output.

For example, a 2020 audit at a UK cement producer revealed £23,500 in annual savings through equipment upgrades.

Common Inefficiencies in Compressed Air Systems

Understanding where inefficiencies occur is crucial for targeting improvements.

Key Problem Areas

- Air Leaks: Up to 40% of compressed air can be lost through leaks, increasing energy costs.

- Over-Pressurisation: Running compressors above required pressure wastes energy (1 bar excess = 7% higher costs).

- Inadequate Piping: Long or poorly designed pipework causes pressure drops and inefficiencies.

- Outdated Equipment: Older compressors lack modern energy-saving features like variable speed drives (VSDs).

- Poor Maintenance: Clogged filters or neglected components reduce performance.

These issues often go unnoticed without a professional audit, silently inflating operational costs.

The Air Compressor Audit Process

A thorough audit combines visual inspections, data logging, and expert analysis to provide a clear picture of system performance.

Types of Audits

- Walk-the-Line Assessment: A cost-effective visual check of compressors, dryers, and piping to identify obvious issues like leaks or poor configuration. Often free, it’s ideal for initial evaluations.

- Data Logging Audit: Uses advanced equipment to monitor energy use, air flow, and pressure over 7-14 days, offering detailed insights.

- Comprehensive AIRScan: A full-system audit, including air quality, leaks, and pressure drops, compliant with ISO 11011 standards.

Steps in a Professional Audit

- System Inventory: Map all components, from compressors to distribution pipes.

- Visual Inspection: Check for leaks, corrosion, or improper setups.

- Data Logging: Install loggers to track power consumption, pressure, and flow.

- Analysis and Simulation: Use software to model savings from upgrades or repairs.

- Report and Recommendations: Receive a detailed report with actionable steps, such as VSD installation or leak repairs.

Audits typically last a week to ensure a complete view of usage patterns, including peaks and weekends.

ISO 11011 Standards and Their Role

ISO 11011:2013 sets the framework for compressed air system assessments, ensuring consistent, reliable audits.

Key Aspects of ISO 11011

- Comprehensive Scope: Evaluates energy input, air demand, pressure, and quality.

- Standardised Reporting: Provides clear, actionable data for decision-makers.

- ISO 50001 Alignment: Serves as a benchmark for energy management certification.

Compliance with ISO 11011 ensures audits deliver measurable, trustworthy results, avoiding flawed recommendations that waste investment.

Energy-Saving Solutions Uncovered by Audits

Audits reveal opportunities to optimise systems with modern technologies and practices.

Recommended Solutions

- Leak Detection and Repair: Use ultrasonic probes to identify and fix leaks, saving up to 20% on energy.

- Variable Speed Drives (VSDs): Adjust compressor output to demand, reducing energy waste.

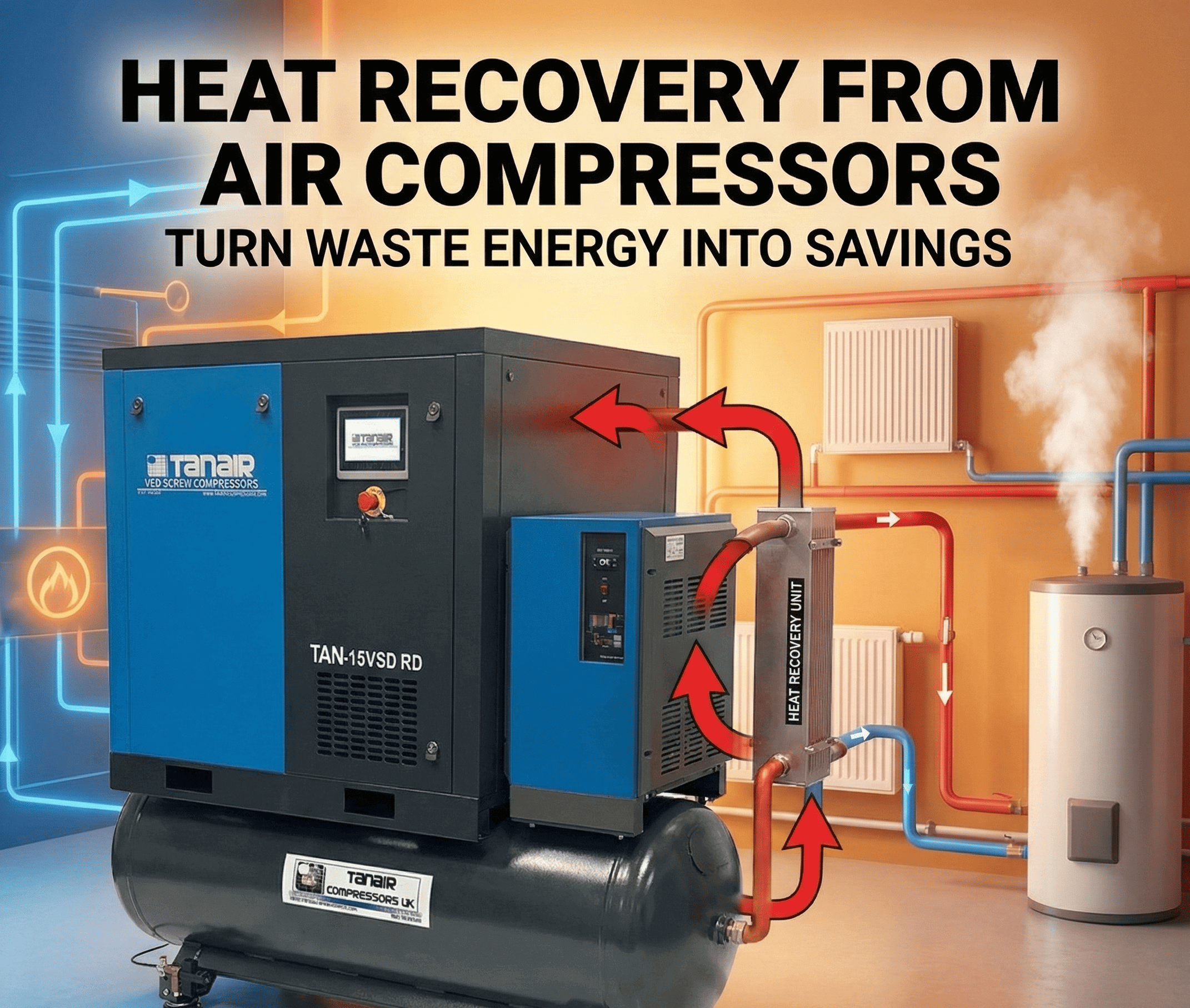

- Heat Recovery Systems: Capture 70-94% of waste heat for heating or hot water, cutting energy costs.

- Pressure Optimisation: Lower pressure settings to match application needs.

- Modern Piping: Upgrade to modular systems like Atlas Copco’s AIRnet for better flow and efficiency.

- Advanced Controllers: Optimise system performance by matching air output to demand.

For instance, installing VSDs can reduce energy consumption by 10-20% on the supply side.

Maintenance Best Practices

- Regularly replace filters and lubricants to maintain efficiency.

- Schedule annual audits to catch new inefficiencies early.

- Monitor ambient conditions to adjust system settings.

Financial and Environmental Impacts

Optimising your system through audits delivers significant benefits.

Financial Savings

- Reduce energy bills by addressing leaks and inefficiencies.

- Lower maintenance costs by preventing equipment damage.

- Achieve fast ROI, with audits often paying for themselves within months.

Environmental Benefits

- Cut CO2 emissions by reducing energy use (e.g., 140 tons/year saved in a cement plant audit).

- Support UK net-zero targets with sustainable practices.

- Enhance corporate reputation with eco-conscious operations.

Choosing a Professional Audit Provider in the UK

Selecting the right provider ensures accurate results and effective solutions.

What to Look For

- Experience: Choose providers with decades of expertise, like Compressed Air Systems UK, with over 30 years in the industry.

- Certified Engineers: Ensure factory-trained staff familiar with ISO standards.

- Advanced Tools: Look for data loggers, ultrasonic probes, and simulation software.

- Custom Solutions: Providers should offer tailored recommendations, from repairs to full system upgrades.

- Local Presence: UK-based providers, especially in the Midlands, offer faster response times.

Compressed Air Systems UK, based in Birmingham, provides 24/7 support and ISO-compliant audits for businesses nationwide.

In summary, air compressor audits are a powerful tool for UK businesses to cut costs, boost efficiency, and meet sustainability goals. By identifying leaks, optimising pressure, and integrating advanced technologies, audits deliver immediate and long-term value. Partner with a trusted provider like Compressed Air Systems UK to unlock your system’s full potential.

Take Control of Your Compressed Air Efficiency Today

Ready to slash energy costs and enhance performance? Contact Compressed Air Systems UK at 0121 753 3330 or visit Unit 15, Fortnum Close, Birmingham, B33 0LG, for a free audit consultation. Let’s optimise your system for a sustainable, cost-effective future!

Frequently Asked Questions About Air Compressor Audits

Curious about how air compressor audits can benefit your business? Our FAQ section answers common questions to help you get started.

- An assessment is a quick, often free, visual check identifying basic issues, while a full audit uses data logging for in-depth analysis over 7-14 days.

Annual audits are recommended, with additional checks after system changes or if energy bills rise unexpectedly.

Yes, audits ensure compliance with ISO 11011 and support ISO 50001 certification for energy management.

Savings can reach 10-30% of energy costs, depending on inefficiencies like leaks or over-pressurisation.

No, modern audits use non-invasive tools like data loggers, allowing production to continue uninterrupted.

Explore More of Our Articles

The Ultimate Guide to Diesel Air Compressors: Power, Portability, and Performance for UK Applications

The Ultimate Guide to Diesel Air Compressors: Power, Portability, and Performance for UK Applications Everything UK professionals need to know about diesel air compressors —

The Ultimate Guide to Petrol Compressors: Portable Power for UK Sites and Workshops

The Ultimate Guide to Petrol Compressors: Portable Power for UK Sites and Workshops Everything UK tradespeople and site managers need to know about petrol compressors

Explore Our Complete Air Compressor Range

Shop the Full Tanair Air Compressor Range Compare portable direct drive, belt-driven workshop and energy-saving VSD compressors — then buy online, call for instant advice,

What Size Air Compressor Do You Need? (CFM, Tank Size & Power Guide UK)

What Size Air Compressor Do I Need? Use this UK-focused guide to calculate CFM, choose the right tank size, and match voltage & duty cycle—then

Heat Recovery from Air Compressors: Turn Waste Energy into Savings for UK Workshops 2026

What if up to 94% of the energy used by your air compressor is converted into heat, much of which is simply wasted, potentially costing

The Ultimate Guide to Air Line Fittings: Types, Uses, and Maintenance for UK Workshops

Did you know that poor quality air line fittings can cause up to 30% energy loss in compressed air systems, costing UK workshops thousands in