Introduction: Embracing Efficiency in Air Compressor Technology

The Critical Role of Energy Efficiency

Today’s industrial landscape demands not only performance but also sustainability and cost-effectiveness in its operations. At Compressed Air Systems UK, we understand the pivotal role that energy efficiency plays in air compressor technology. Our commitment to innovation is driven by the need to offer solutions that not only serve operational requirements but also contribute significantly to reducing energy consumption and environmental impact.

Advancements in Compressor Technology

In our quest to meet these demands, we introduce cutting-edge air compressors equipped with Permanent Magnet motors. These advanced units stand at the forefront of compressor technology, offering unmatched efficiency. By integrating Permanent Magnet motors, our compressors achieve higher efficiency levels compared to traditional models, leading to substantial reductions in operational costs and promoting environmental sustainability. This technology exemplifies our dedication to providing state-of-the-art solutions that align with the global shift towards energy conservation and reduced carbon footprints.

Through these efforts, Compressed Air Systems UK is not just supplying equipment; we’re offering a pathway to a more sustainable and cost-effective future in compressed air systems.

The Strategic Advantage of Energy-Efficient Air Compressors

Air Compressors Across Industries

Air compressors are indispensable in diverse sectors, including manufacturing, construction, and pharmaceuticals, due to their versatility and efficiency. Their role in powering tools, and process lines, and providing critical clean air supply underpins the operational backbone of these industries. However, this wide-ranging applicability comes with significant energy demands, making air compressors a substantial component of a facility’s energy consumption profile.

Unlocking Cost Savings through Efficiency

Investing in energy-efficient air compressor models, particularly those with advanced technologies like Permanent Magnet motors, presents a significant opportunity for energy and cost savings. These models are designed to optimise energy use, translating to lower electricity bills and a reduced environmental footprint. By prioritising efficiency, businesses can achieve a dual benefit: sustaining their operational needs while minimising energy expenses. The potential savings are not just immediate but extend throughout the lifespan of the compressor, offering a compelling case for investing in energy-efficient solutions.

-

Rated 0 out of 5Sale!Add to basket

Rated 0 out of 5Sale!Add to basket£20,513.00Original price was: £20,513.00.£12,308.00Current price is: £12,308.00. exc vat. -

Rated 0 out of 5Sale!Add to basket

Rated 0 out of 5Sale!Add to basket£23,444.00Original price was: £23,444.00.£14,066.00Current price is: £14,066.00. exc vat. -

Rated 0 out of 5Sale!Add to basket

Rated 0 out of 5Sale!Add to basket£21,056.00Original price was: £21,056.00.£12,634.00Current price is: £12,634.00. exc vat. -

Rated 0 out of 5Sale!Add to basket

Rated 0 out of 5Sale!Add to basket£24,203.00Original price was: £24,203.00.£14,522.00Current price is: £14,522.00. exc vat. -

Rated 0 out of 5Sale!Add to basket

Rated 0 out of 5Sale!Add to basket£30,965.00Original price was: £30,965.00.£18,579.00Current price is: £18,579.00. exc vat. -

Rated 0 out of 5Sale!Add to basket

Rated 0 out of 5Sale!Add to basket£36,408.00Original price was: £36,408.00.£21,845.00Current price is: £21,845.00. exc vat. -

Rated 0 out of 5Sale!Add to basket

Rated 0 out of 5Sale!Add to basket£33,665.00Original price was: £33,665.00.£19,628.00Current price is: £19,628.00. exc vat. -

Rated 0 out of 5Sale!Add to basket

Rated 0 out of 5Sale!Add to basket£38,189.00Original price was: £38,189.00.£22,913.00Current price is: £22,913.00. exc vat.

Decoding Air Compressor Efficiency

The Evolution of Compressor Technologies

In the realm of air compressor technology, efficiency has evolved from a desirable trait to a critical demand. This section delves into the mechanics behind the most efficient compressors on the market, particularly those powered by Permanent Magnet (PM) motors. These advanced motors represent a significant leap over traditional models, offering superior efficiency by minimising electrical losses and optimising output.

The Advantages of Permanent Magnet Motors

Permanent Magnet motors stand out for their ability to maintain high efficiency across a wide range of loads. This adaptability ensures that energy consumption closely aligns with the demand, avoiding the wasteful excess common in fixed-speed models. The benefits are manifold, including:

- Reduced Energy Consumption: PM motors significantly lower the energy requirements of air compressors, leading to direct savings on utility bills.

- Extended Lifespan: By operating more efficiently and generating less heat, these compressors enjoy a longer operational life.

- Cost Savings Over Time: The initial investment in a PM motor compressor is offset by the substantial energy and maintenance savings achieved over its lifespan.

Understanding Your Needs: Flow Rate, Power, and Pressure

Selecting the right air compressor for your specific needs requires a detailed understanding of three key parameters: flow rate, power, and pressure. These factors are critical in ensuring your compressor not only meets but exceeds your operational requirements without excess expenditure on unused capacity.

- Flow Rate (CFM): The volume of air a compressor can produce at a given pressure, measured in cubic feet per minute (CFM). It’s crucial to match this with the air demand of your tools or processes to ensure efficiency.

- Power (HP): Indicates the horsepower of the compressor, affecting its ability to generate the required pressure and flow rate for your applications.

- Pressure (PSI): The maximum pressure output of the compressor, measured in pounds per square inch (PSI). Different tools and processes require different pressures for optimal operation.

Air Tool | Air Pressure (bar) | Average Air Consumption (CFM) |

Air Drill | 6.2 | 4.5 |

Angle Grinder 5″ | 6.2 | 5.5 |

Belt Sander 3″ | 6.2 | 6.5 |

Caulking Gun | 6.2 | 1.5 |

Hammer/Chisel | 6.2 | 4.5 |

Cut Off Tool 1/2″ | 6.2 | 5.0 |

Die Grinder | 6.2 | 8.5 |

Orbital Sander | 6.2 | 6.5 |

High Speed Grinder | 6.2 | 5.5 |

Hydraulic Riveter | 6.2 | 4.5 |

Impact Wrench 1″ | 6.2 | 12.5 |

Impact Wrench 1/2″ | 6.2 | 4.5 |

Long Bed Sander | 6.2 | 9.0 |

Mini Die Grinder | 6.2 | 8.5 |

Needle Scaler | 6.2 | 5.0 |

Orbital Sander 5″ | 6.2 | 6.5 |

Punch and Flange Tool | 6.2 | 0.5 |

Ratchet 3/4″ | 6.2 | 7.0 |

Shears | 6.2 | 5.5 |

Spray Gun | 6.2 | 9.5 |

Sandblaster Small | 6.2 | 10.0 |

Sandblaster Medium | 6.2 | 20.0 |

Sandblaster Large | 6.2 | 45.0 |

Air Compressor Pump Small | 6.2 | 15.0 |

Air Compressor Pump Medium | 6.2 | 25.0 |

Air Compressor Pump Large | 6.2 | 40.0 |

Paint Sprayer | 6.2 | 12.0 |

Grease Gun | 6.2 | 4.0 |

Air Blow Gun Small | 6.2 | 2.0 |

Air Blow Gun Medium | 6.2 | 3.0 |

Air Blow Gun Large | 6.2 | 5.0 |

Air Body Saw | 6.2 | 6.0 |

Air Flange | 6.2 | 3.0 |

Air Hydraulic Rivet Gun | 6.2 | 4.0 |

Backfill Tamper | 6.2 | 20.0 |

Pneumatic Deadman Controls | 6.2 | 2.0 |

Conclusion: Embracing Efficiency in Compressed Air Systems

Investing in an efficient air compressor is more than just a purchase; it’s a commitment to sustainability, operational excellence, and cost-effectiveness. With these insights, you’re now equipped with the knowledge to not only choose the right equipment but also implement practices that maximise its potential while minimising its footprint.

But understanding the path to efficiency is just the beginning. Implementing it can be a nuanced challenge, which is where our expertise comes in. At Compressed Air Systems UK, we’re not just suppliers; we’re partners in your journey towards enhanced efficiency.

Here to Help 24/7

Contacting Compressed Air Systems UK couldn’t be easier! Whether you’re in the market for the latest in air compressor technology, require bespoke solutions, or simply want to explore ways to make your current system more energy-efficient, we’re here to provide the support you need.

Get in Touch Today:

- Call Us: For immediate assistance and peace of mind, our phone lines are monitored 24/7. Dial 01217533330 for support at any hour.

- Send Us a Message: If you prefer to reach out digitally, send us a message through our contact form and we’ll aim to respond within the hour.

- Chat with Us: For quick queries and conversations, use our chat feature — we’d love to assist you in real time.

Remember, every step you take towards efficiency not only benefits your bottom line but also contributes to a greener planet. Let’s work together to find the perfect balance of performance and efficiency for your needs.

Visit Us: If you’re in the area and would like to discuss your needs in person, our offices, trade counter, and warehouse are located at Compressed Air Systems UK, Unit 15, Fortnum Close, Birmingham, B33 0LG. Need directions or have specific inquiries? Don’t hesitate to call us at 01217533330.

Join us in forging a future where efficiency is not an option but a standard. We’re here, ready to help — 24/7.

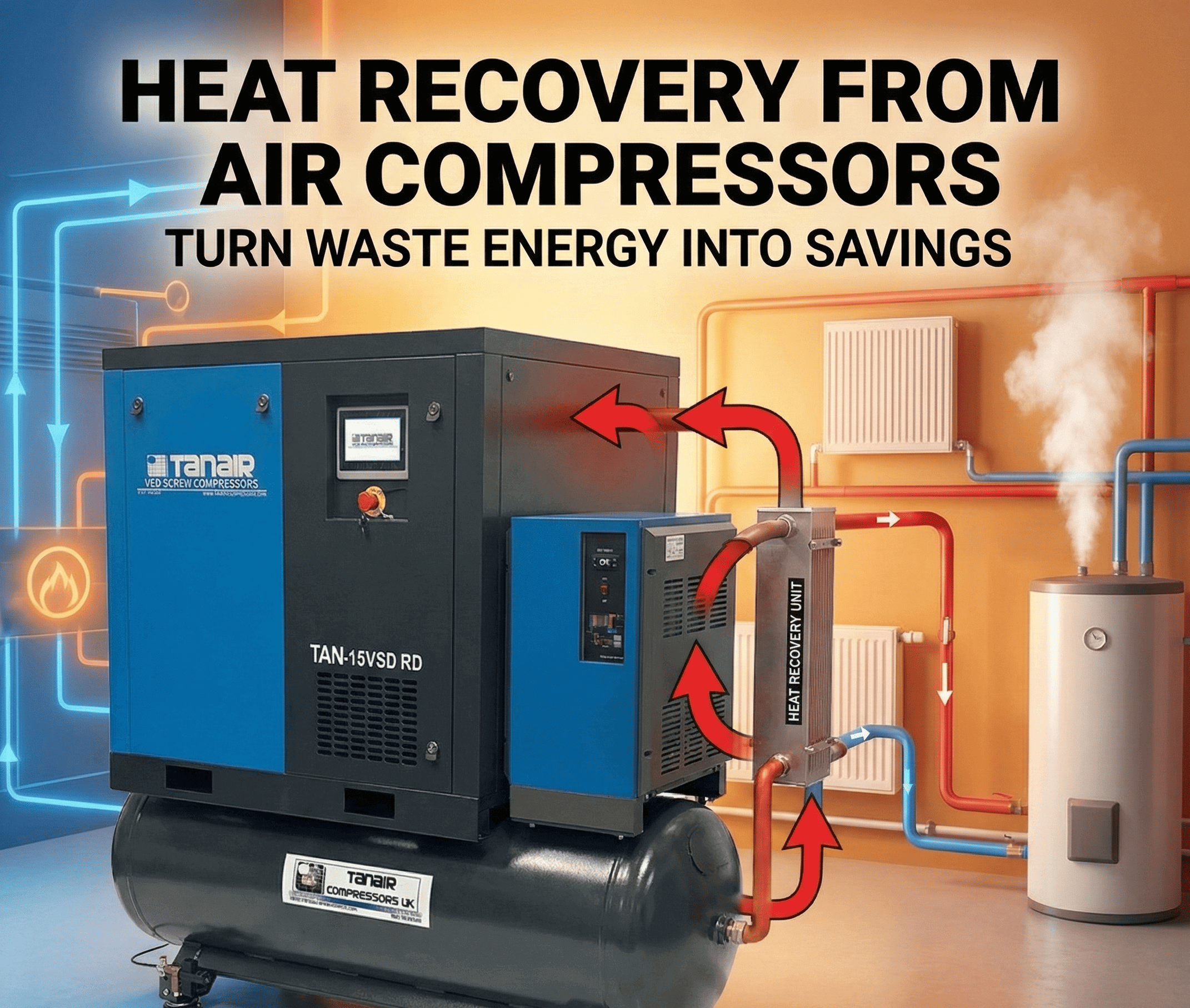

Heat Recovery from Air Compressors: Turn Waste Energy into Savings for UK Workshops 2026

What if up to 94% of the energy used by your air compressor is converted into heat, much of which

The Benefits of Deep Cleaning Your Compressed Air System

Did you know that accumulated contaminants in compressed air systems can cause up to 30% energy waste, adding thousands to

The Ultimate Guide to Air Line Fittings: Types, Uses, and Maintenance for UK Workshops

Did you know that poor quality air line fittings can cause up to 30% energy loss in compressed air systems,

Wall-Mounted Air Compressors: The Ultimate Space-Saving Guide for UK Garages in 2025/26

Did you know that the average UK garage loses up to 2 square metres of valuable floor space to a

The True Cost of Compressor Downtime in Tamworth’s Industrial Sector

Did you know that a single hour of compressor downtime in a mid-sized manufacturing plant can cost up to £10,000

Air Compressor Kits vs Standalone Tools: Which Setup Saves You Time and Money in the UK?

Did you know that over 70% of UK DIY enthusiasts end up spending an extra £150 or more piecing together