A failing start capacitor is one of the most common reasons your air compressor motor hums but won’t start – and it could be costing you valuable time and money.

- Is your 2.2 kW air compressor motor humming but refusing to start?

- Wondering why your compressor struggles to reach full speed or overheats?

- Curious how a small, inexpensive part could save your motor from costly damage?

What You’ll Learn

- The crucial role of the start capacitor in your 2.2 kW air compressor motor

- Common symptoms indicating a failing start capacitor

- How to safely inspect and diagnose capacitor issues

- Why our 230–315 µF 250 V start capacitor is the ideal replacement

- Tips for easy replacement and maintenance to keep your compressor running smoothly

Introduction

The start capacitor is a small but vital component in your 2.2 kW 230-volt single-phase air compressor motor. It provides the essential electrical boost needed to get your motor spinning from a standstill. When this capacitor fails, your compressor motor may hum, struggle to start, or overheat, leading to frustrating downtime and potential motor damage. Understanding the symptoms of a failing start capacitor and knowing how to replace it can save you time, money and hassle.

What Does a Start Capacitor Do in an Air Compressor?

Your air compressor’s motor relies on a start capacitor to deliver a high-energy jolt of electricity during startup. This surge creates a phase shift in the motor windings, generating the torque necessary to overcome inertia and begin rotation. Without a functioning start capacitor, the motor may receive power but fail to start turning, resulting in a humming noise and inefficient operation.

Think of the start capacitor as a temporary electrical “boost” that helps the motor overcome the initial resistance when starting under load. Once the motor reaches around 75% of its full speed, a centrifugal switch disconnects the start capacitor from the circuit, allowing the motor to run normally. Additionally, a good start capacitor helps protect the motor from overheating by ensuring a smooth and efficient startup process.

Common Symptoms of a Failing Start Capacitor in Air Compressors

- Humming but no start: The motor hums but doesn’t spin, indicating insufficient starting torque.

- Slow or intermittent starting: The motor struggles to reach operating speed or starts inconsistently.

- Motor overheating: Excessive current draw causes the motor to heat up, risking damage.

- Visible capacitor damage: Bulging, leaking, or cracked capacitor casing signals failure.

- Compressor stops shortly after starting: The motor cuts out or trips thermal overload protection.

If you notice any of these signs, it’s likely your start capacitor is failing or has failed, and immediate replacement is recommended to avoid further damage.

How to Inspect and Diagnose Your Start Capacitor

- Visual check: Look for bulging tops, fluid leaks, or cracked casing on the capacitor. These are clear physical signs of failure.

- Safety first: Always disconnect power from the compressor and safely discharge the capacitor before handling it to avoid electric shock.

- Electrical testing: Use a multimeter with capacitance measurement capability to verify the capacitor’s health. If you’re unsure how to do this safely, seek professional assistance.

- Relay check: A faulty start relay can cause the capacitor to remain engaged too long, leading to premature failure. It’s advisable to inspect or test the relay alongside the capacitor.

Why Choose Our 230 – 315 µF Start Capacitor 250 V for Your 2.2 kW Air Compressor Motor?

- Perfectly matched: Specifically designed for 2.2 kW 230 V single-phase motors, ensuring optimal compatibility and performance.

- Durable and reliable: Built for intermittent AC duty with a rugged plastic case to withstand tough operating conditions and provide a long service life.

- Restore motor efficiency: Quickly regain starting torque and prevent overheating issues, helping your compressor run smoothly and reliably.

- Peace of mind: Backed by a 6-month warranty and supported by over 30 years of industry expertise from Compressed Air Systems UK.

- Fast availability: Our capacitors are held in stock with rapid delivery options to minimise your compressor downtime.

Easy Replacement and Maintenance Tips

Replacing your start capacitor is straightforward thanks to its standard terminals, making installation simple for those with basic electrical knowledge. However, if you are unsure or unfamiliar with electrical components, we strongly recommend seeking professional installation to ensure safety and correct fitting.

Regular inspection of your air compressor’s start capacitor can help prevent unexpected failures and costly repairs. Look out for any signs of wear or damage during routine maintenance checks, and replace the capacitor proactively if you notice any issues.

At Compressed Air Systems UK, we offer expert maintenance services and 24/7 emergency repair support to keep your compressor running smoothly and minimise downtime. Our experienced engineers are on hand to assist with servicing, repairs, and component replacements whenever you need them.

Conclusion

If your 2.2 kW air compressor motor is humming, starting slowly, or overheating, it’s time to check your start capacitor. Replacing a faulty capacitor with our high-quality 230 – 315 µF 250 V start capacitor can restore your motor’s reliable operation and extend its lifespan.

Don’t let a small component cause big problems — contact Compressed Air Systems UK today to order your capacitor or get expert advice from our knowledgeable team. We’re here to help you keep your air compressor running at peak performance.

Compressed Air Systems UK: Your One-Stop Shop for Capacitors and Spares for Your Air Compressor

At Compressed Air Systems UK, we pride ourselves on being your trusted partner for all air compressor parts and accessories. Whether you need start capacitors, replacement spares, or full maintenance support, we stock a wide range of high-quality components designed to fit and perform perfectly with your equipment.

With over 30 years of industry experience, factory-trained engineers, and a commitment to excellent customer service, we provide fast delivery, competitive pricing, and expert advice to keep your operations running smoothly. Choose Compressed Air Systems UK — the dependable choice for air compressor capacitors and spares.

Explore More of Our Articles

The Ultimate Guide to Diesel Air Compressors: Power, Portability, and Performance for UK Applications

The Ultimate Guide to Diesel Air Compressors: Power, Portability, and Performance for UK Applications Everything UK professionals need to know about diesel air compressors —

The Ultimate Guide to Petrol Compressors: Portable Power for UK Sites and Workshops

The Ultimate Guide to Petrol Compressors: Portable Power for UK Sites and Workshops Everything UK tradespeople and site managers need to know about petrol compressors

What Size Air Compressor Do You Need? (CFM, Tank Size & Power Guide UK)

What Size Air Compressor Do I Need? Use this UK-focused guide to calculate CFM, choose the right tank size, and match voltage & duty cycle—then

Explore Our Complete Air Compressor Range

Shop the Full Tanair Air Compressor Range Compare portable direct drive, belt-driven workshop and energy-saving VSD compressors — then buy online, call for instant advice,

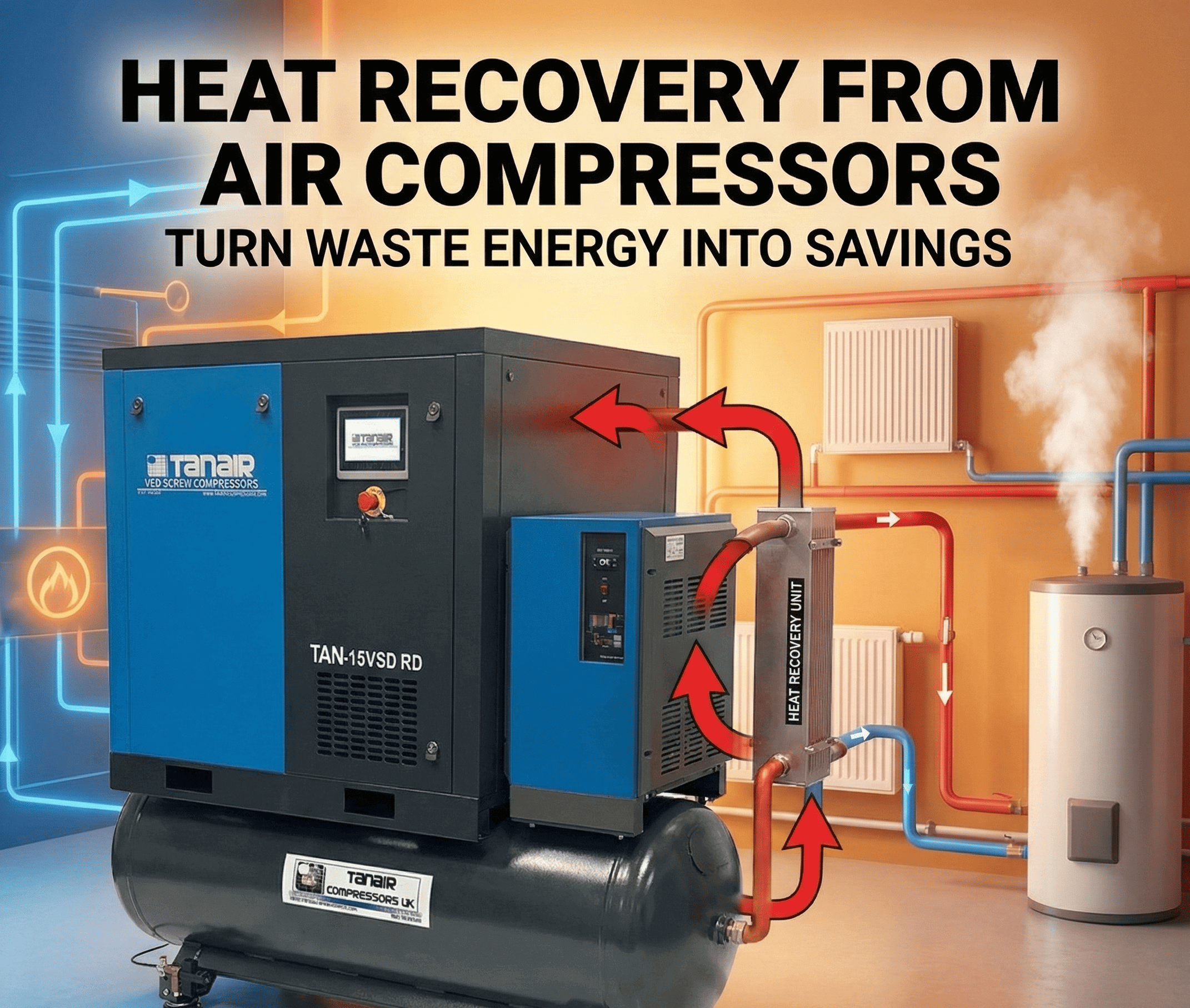

Heat Recovery from Air Compressors: Turn Waste Energy into Savings for UK Workshops 2026

What if up to 94% of the energy used by your air compressor is converted into heat, much of which is simply wasted, potentially costing

The Benefits of Deep Cleaning Your Compressed Air System

Did you know that accumulated contaminants in compressed air systems can cause up to 30% energy waste, adding thousands to annual electricity costs for UK