“Proper storage and handling of air hoses can prevent costly damage, reduce workplace hazards, and extend the life of your equipment. Are you storing your hoses safely?”

- Why is correct hose storage crucial for safety and longevity?

- What are the common risks of improper hose handling?

- How can simple best practices improve workplace safety?

Key Areas to Cover

- Importance of proper storage and handling for air hose safety

- Best practices for coiling, hanging, and storing air hoses

- Avoiding tripping hazards and hose kinks

- Environmental factors affecting hose storage (temperature, humidity, light, ozone)

- Recommended storage conditions and handling methods

- Use of hose reels and accessories to enhance safety and organisation

- Regular inspection and maintenance tips

- Link to service or product page for hose reels and accessories

Introduction

Air hoses are vital components in many industrial and commercial settings, but improper storage and handling can lead to premature wear, safety hazards, and costly downtime. This article outlines best practices for storing and handling air hoses to maximise safety, maintain hose integrity, and ensure reliable performance. Following these guidelines helps prevent accidents such as tripping or hose failure and extends the lifespan of your equipment.

No posts found!

Importance of Proper Storage and Handling

Proper storage and handling of air hoses are essential to prevent damage such as kinks, cracks, and abrasions. These issues not only reduce the hose’s lifespan but can also lead to sudden failures that disrupt operations. Additionally, correctly stored hoses reduce workplace hazards, including tripping and slipping accidents caused by hoses left lying around carelessly. Maintaining hose integrity through good storage practices ensures consistent performance and extends the service life of your equipment, saving costs and downtime in the long run.

Best Practices for Coiling and Hanging Air Hoses

When coiling air hoses, it is important to do so neatly and without exceeding the manufacturer’s recommended bend radius to avoid creating kinks that weaken the hose structure. Using hose reels or hangers is highly recommended to keep hoses off the ground and away from walkways, which helps prevent damage and reduces trip hazards. Avoid stacking hoses directly on top of each other, as this can cause deformation and premature wear.

Avoiding Tripping Hazards and Hose Kinks

To minimise the risk of trips and falls, store air hoses away from high-traffic areas or clearly mark their locations if hoses must cross walkways. Selecting the appropriate hose length for the task at hand is also crucial to avoid excess hose lying on the floor, which can become a hazard. Regular inspections should be carried out to identify any signs of damage or wear, such as cracks or soft spots, which could lead to hose failure and safety risks.

Environmental Factors Affecting Hose Storage

Air hoses should be stored in cool, dry, dust-free, and well-ventilated areas, avoiding drafts that can introduce moisture or contaminants. Ideally, storage temperatures should be maintained between 0°C and 25°C to prevent brittleness or degradation caused by extreme heat or cold. Hoses must be protected from direct sunlight and ultraviolet (UV) rays, as well as ozone exposure from nearby electrical equipment, which can deteriorate hose materials. Additionally, avoid storing hoses near oils, solvents, grease, or chemicals that could damage the hose surface or compromise its integrity.

Recommended Storage Methods

When storing air hoses, use the largest possible diameter for coils and storage drums to prevent unnecessary stress and deformation. Keeping hoses unconstrained is vital—avoid piling or compressing them, as this can cause permanent damage or weaken the hose structure. Additionally, retaining the original packaging and placing caps on hose ends during storage helps prevent contamination from dust, dirt, and moisture, ensuring the hose remains clean and ready for use.

No posts found!

Handling Methods

Air hoses should be handled with care to avoid physical damage such as cuts, abrasions, or unnecessary bending that could compromise their integrity. For heavy or long hoses, use appropriate lifting equipment to reduce strain on both the hose and personnel. It is also important to train staff on correct hose handling and storage procedures to maintain workplace safety and extend the lifespan of your hoses.

Hose Reels and Accessories

Hose reels are an excellent solution for organising air hoses, reducing wear caused by dragging or kinking, and eliminating trip hazards by keeping hoses neatly coiled and off the floor. Accessories such as protective covers and specialised fittings further enhance hose durability and safety by shielding hoses from abrasion and ensuring secure connections. For effective hose management solutions, explore our range of hose reels and accessories.

Regular Inspection and Maintenance

Regular inspection is essential for maintaining air hose safety and performance. Before each use, check hoses for visible signs of damage such as cracks, leaks, soft spots, or bubbles. Also, inspect fittings and connections to ensure they are tight and free from wear or corrosion. Any damaged hoses should be replaced immediately to prevent accidents, equipment failure, and costly downtime.

Conclusion

Proper storage and handling of air hoses are fundamental to ensuring workplace safety, preventing costly damage, and maximising the lifespan of your equipment. By following best practices such as correct coiling, using hose reels, avoiding tripping hazards, and protecting hoses from environmental damage, you can maintain optimal hose performance and reduce downtime. Regular inspection and maintenance further safeguard your operations by identifying potential issues before they escalate.

Keep Your Operations Running Smoothly with Compressed Air Systems UK

Ready to take your air hose safety and efficiency to the next level? Trust Compressed Air Systems UK for expert advice, high-quality products, and outstanding service.

Whether you need hose reels, accessories, or a complete compressed air solution, our experienced team is here to help you find exactly what you need.

Visit our website today and discover why businesses across the UK have relied on us since 1992.

Explore More of Our Articles

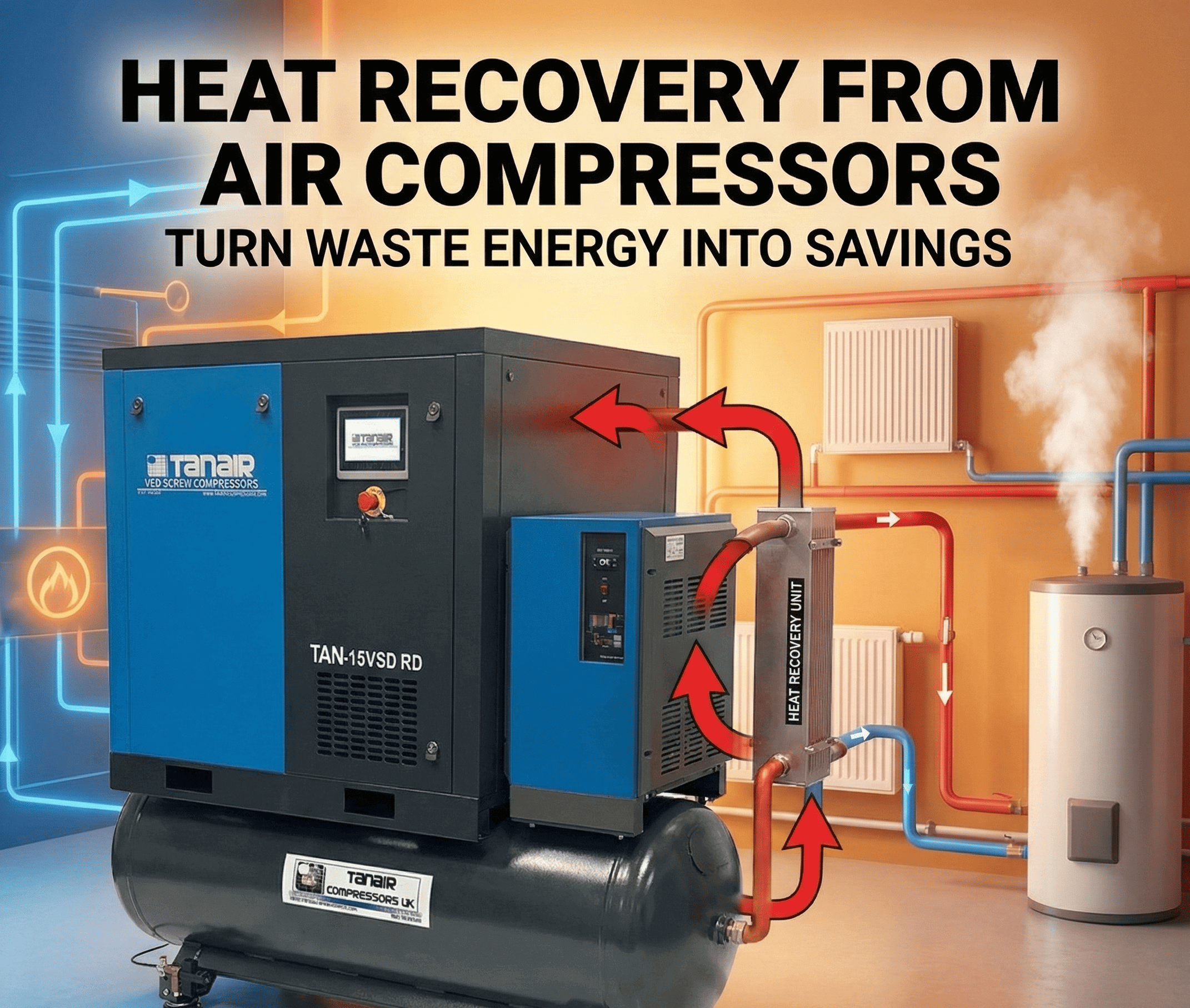

Heat Recovery from Air Compressors: Turn Waste Energy into Savings for UK Workshops 2026

What if up to 94% of the energy used by your air compressor is converted into heat, much of which is simply wasted, potentially costing

The Benefits of Deep Cleaning Your Compressed Air System

Did you know that accumulated contaminants in compressed air systems can cause up to 30% energy waste, adding thousands to annual electricity costs for UK

The Ultimate Guide to Air Line Fittings: Types, Uses, and Maintenance for UK Workshops

Did you know that poor quality air line fittings can cause up to 30% energy loss in compressed air systems, costing UK workshops thousands in

Wall-Mounted Air Compressors: The Ultimate Space-Saving Guide for UK Garages in 2025/26

Did you know that the average UK garage loses up to 2 square metres of valuable floor space to a traditional air compressor – enough

The True Cost of Compressor Downtime in Tamworth’s Industrial Sector

Did you know that a single hour of compressor downtime in a mid-sized manufacturing plant can cost up to £10,000 in lost production alone? In

Air Compressor Kits vs Standalone Tools: Which Setup Saves You Time and Money in the UK?

Did you know that over 70% of UK DIY enthusiasts end up spending an extra £150 or more piecing together mismatched air tools that fail